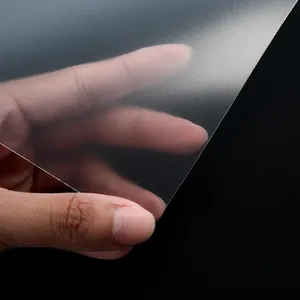

Giới thiệu về bảng pcb trong suốt

Alibaba.com cung cấp các sản phẩm 3760 bảng pcb trong suốt. Có rất nhiều bảng pcb trong suốt lựa chọn dành cho bạn, chẳng hạn như nhà sản xuất, oem, và nhà máy. Bạn cũng có thể chọn từ thiết bị điện tử, thông tin liên lạc, và oem điện tử bảng pcb trong suốt. Cũng như từ hasl, hasl chì miễn phí bảng pcb trong suốt.