All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(Có 5 sản phẩm)

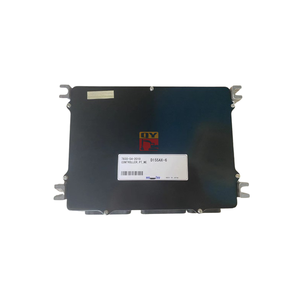

Alibaba.com là nền tảng số một để tìm các sản phẩm tốt nhất cho nhu cầu của bạn. Nó bao gồm tất cả yêu thích của bạn. hộp điều khiển JCB 35B. mà bạn cần trong cuộc sống của bạn. Bạn sẽ tìm thấy tốt nhất và lâu dài. hộp điều khiển JCB 35B trên nền tảng này. Nếu bạn là một nhà xây dựng, bạn chắc chắn cần phải xem những sản phẩm tuyệt vời trên nền tảng này. Tất cả những thứ này. hộp điều khiển JCB 35B. thân thiện với người dùng. Vì vậy, bạn không cần phải lo lắng nhiều về cách sử dụng của nó. Bạn cũng có thể tìm thấy một loạt các sản phẩm danh mục khác nhau trên nền tảng này. Tất cả các loại sản phẩm đều có sẵn trên nền tảng này với mức chiết khấu siêu khủng mà bạn chưa bao giờ tưởng tượng được.

Tại Alibaba.com, bạn không chỉ tìm thấy những mặt hàng tốt. hộp điều khiển JCB 35B nhưng đồng thời, bạn sẽ thấy rằng những điều này. hộp điều khiển JCB 35B chứa chất lượng tốt nhất kéo dài hơn. Tất cả những điều hấp dẫn. hộp điều khiển JCB 35B có các kích thước, khối lượng và độ dài khác nhau. Các sản phẩm này được sản xuất bằng vật liệu dễ phân hủy.

Các nhà sản xuất của những điều đáng kinh ngạc. hộp điều khiển JCB 35B có nhiều kinh nghiệm trong việc sản xuất những chất lượng tốt nhất này. hộp điều khiển JCB 35B. Phần tốt nhất về nền tảng này là các nhà cung cấp trong nền tảng này cung cấp cho bạn một tùy chọn tùy chỉnh. Bạn có thể tùy chỉnh nó phù hợp với nhu cầu của bạn. Những .. hộp điều khiển JCB 35B này được sản xuất theo cách mà mọi người dân đều có thể sử dụng nó mà không gặp bất kỳ vấn đề gì.

Tại Alibaba.com, bạn có thể tìm thấy tất cả các phạm vi. hộp điều khiển JCB 35B. phù hợp nhất cho bạn. Bạn sẽ không thể tìm thấy những loại ưu đãi và chiết khấu thú vị này trên bất kỳ nền tảng nào khác.