All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

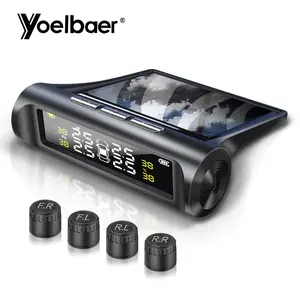

Việc đo áp suất lốp trở nên đơn giản và chính xác với những tính năng hoàn hảo này. tpms bên ngoài trên Alibaba.com. Những cái này. tpms bên ngoài trao quyền cho người dùng của họ để tạo lại độ tin cậy của các kết quả mà họ nhận được từ việc đo áp suất lốp của họ. Với những giao dịch hấp dẫn, những. tpms bên ngoài có giá trị cao. Chúng cực kỳ linh hoạt và có thể áp dụng cho nhiều loại lốp khác nhau, từ ô tô hạng nhẹ đến xe hạng nặng.

Những loại lốp này. tpms bên ngoài được làm bằng vật liệu chắc chắn giúp tăng tuổi thọ lâu dài của việc cung cấp dịch vụ hoàn hảo. Các phát minh công nghệ cao làm cho. tpms bên ngoài chính xác khi được sử dụng đúng cách, một tính năng cần thiết ảnh hưởng đến quyết định thêm hoặc duy trì một số đọc áp suất nhất định. Những cái này. tpms bên ngoài có một bộ sưu tập toàn diện gồm các mẫu và kích thước đa dạng, chẳng hạn như loại kỹ thuật số và loại tương tự để đảm bảo rằng mỗi người mua sắm tìm thấy loại phù hợp nhất theo nhu cầu của họ.

Tất cả. tpms bên ngoài được liệt kê tại Alibaba.com rất dễ làm việc vì khả năng nắm bắt tuyệt vời của họ. Chúng yêu cầu nỗ lực bảo trì tối thiểu vì chúng hiếm khi trục trặc hoặc hỏng hóc. Một trong sô đo. tpms bên ngoài rất linh hoạt để mang lại sự thuận tiện cho người dùng của họ bằng cách có thể sử dụng ở bất kỳ vị trí nào. Trang web có những người bán đáng tin cậy, những người đã được chứng minh lịch sử cung cấp các mặt hàng chất lượng một cách nhất quán. Điều này đảm bảo cho người mua hàng rằng chỉ cao cấp. tpms bên ngoài được phân phối với mỗi lần mua hàng.

Người dùng sẽ được hưởng lợi tức đầu tư tối đa bằng cách chọn cách hợp lý nhất. tpms bên ngoài các tùy chọn cho chúng. Tại Alibaba.com, việc mua sắm trở nên vô cùng tiện lợi vì nó tiết kiệm thời gian và tiền bạc trong khi mang đến những sản phẩm hàng đầu. Với mức giá chiết khấu không thể cưỡng lại được thiết kế để mua số lượng lớn ,. Các nhà cung cấp tpms bên ngoài thúc đẩy lợi nhuận tốt hơn cho các nhà kinh doanh mua những mặt hàng này làm hàng tồn kho cho doanh nghiệp của họ.