Giới thiệu về tấm xốp eva

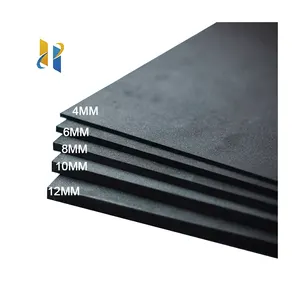

Alibaba.com cung cấp các sản phẩm 23714 tấm xốp eva. Có rất nhiều tấm xốp eva lựa chọn dành cho bạn, chẳng hạn như eva, eva bọt, và cao su. Bạn cũng có thể chọn từ đen, trắng, và màu đỏ tấm xốp eva. Cũng như từ khuôn, cắt, và in ấn tấm xốp eva.Và bất kể tấm xốp eva là thân thiện với môi, không thấm nước, hay chống sốc.