All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(Có 7 sản phẩm)

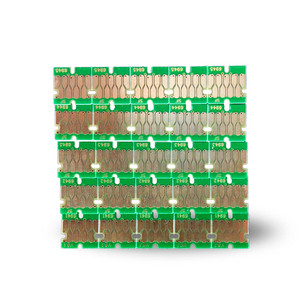

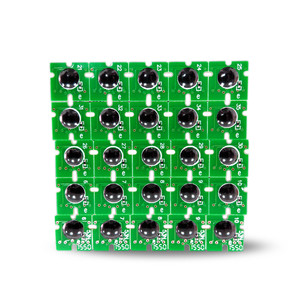

Bán buôn chip tự động đặt lại epson xp800 là một danh mục trình bày nhiều lựa chọn về các bản dựng khác nhau của chip tự động đặt lại epson xp800 cho các máy in khác nhau. Ngoài việc theo dõi mức mực được sử dụng, họ cũng có thể theo dõi số lượng trang được sử dụng trong quá trình in. Các chip mực này thường được hàn vào bảng mạch PCB và đi kèm với máy in. Tuy nhiên, nếu khách hàng của bạn yêu cầu thay thế, sửa chữa hoặc là doanh nghiệp cung cấp các dịch vụ sản xuất và bảo trì này cho người khác, bạn có thể muốn cung cấp chip tự động đặt lại epson xp800 để phục vụ nhu cầu của họ.

Các kích thước khác nhau của chip tự động đặt lại epson xp800 được sử dụng cho các điều khiển máy in khác nhau. Bạn có thể mua bộ đặt lại chip hộp mực cho các keyword máy in và các phụ kiện thay thế chip mực tại đây. Bạn cũng có thể mua các công cụ cần thiết để thiết lập hoặc gắn các chip resetter này vào vị trí chính xác trên máy in. Có rất nhiều giao dịch bán buôn tuyệt vời ở đây, vì vậy hãy xem!

Mua sỉ chip tự động đặt lại epson xp800 ở đây sẽ cho phép bạn tận hưởng tất cả các keyword giá rẻ tuyệt vời. Bạn thậm chí có thể tìm thấy những sản phẩm đầu ngành tuyệt vời. Tại đây có bán nhiều mẫu thiết bị đặt lại chip khác nhau với một số mức giá phải chăng nhất. Hộp mực có thể nạp lại hoặc hộp mực không nạp được; mô hình chip hoặc không chip; Không thể quá chú trọng đến các tùy chọn in được giao tiếp hiệu quả giữa các thành phần khác nhau của máy in.

Mua bộ đặt lại hộp mực tại đây với giá hấp dẫn. Alibaba.com cung cấp nhiều chip tự động đặt lại epson xp800 khác nhau chắc chắn sẽ làm tăng giá trị cho khách hàng của bạn. Mua sắm ngay bây giờ để tận hưởng tất cả các keyword ưu đãi đặc biệt.