Laser Cutting Machine High Speed 3kw 4kw Laser Cutting Machine For Sheet Metal

Wood 1200mm X 900mm Co2 Laser Cutter And Engraver

HGTECH 1325 Series Non-metal Leather Wood Paper Plastic CO2 Laser Cutter Engraver 300W 500W Laser Cutting Machine For Acrylic

Plastic Wood 100w 200w Or 300 Watt Laser Cutter

SENFENG New Generation Good Price 1500*3000 Fiber Laser Metal Cutting Machine 1500w For Sale

150w CO2 Laser Cutter For Wood And MDF And Acrylic

Hot Sale PVC Pipe And Tube 3D Tube Laser cutting machines Pipe Cutter For Quality Product Price

6090 laser engraving machine machine engraving laser price 150W laser cutter

laser cutting machine 1610 1810 1390 CO2 laser cutter printer machine 100w for acrylic wood plastic cnc factory price

Laser Cutting Machine 1000W 1500W 2000W 3000W Price CNC Fiber Laser Cutter Sheet Metal

low price 130w cutter 80w price mini laser engraving machine

factory price wood acrylic Rubber Stamp 40w 50w 3020 cheap laser cutter glass engraving machine

Algolaser DIY KIT CO2 CNC Laser Cutter for Wood and Metal Acrylic Glass

voiern 6040 4060 60w 80w 100w 3d co2 laser engraver and laser cutter machine price for wood with ruida m2 system

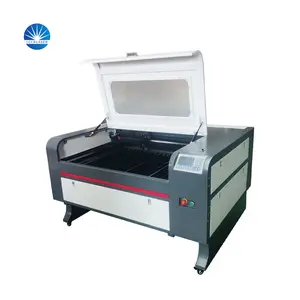

Ruida System 6090 CO2 Laser Engraver Laser Cutting Machine Cnc Laser Cutter Price Wood Engraver Woodworking Machinery Bench-top

Laser Engraver Cutter Wood Metal Laser Engraving Machines Customized CO2 Machine Glass Mini Best Price 4060 Desktop 50W 60W

Cnc Co2 Laser Engrave Cutting Machine Low Price Laser Cutter Co2

China Laser Equipment 1390 80w 3d Crystal Acrylic Wood Laser Cutter Cnc Co2 Cutting Machines Price Laser Engraving Machine

Worth Buying 4060 60W engraving machine price desktop laser cutter

SCULPFUN S6 PRO Engraving Machine wood laser cutter 60W cnc laser cutting machine with good price

Automatic home glowforge 3d crystal hobby CO2 laser printer&cutter&engraving machine for wood material

100W CO2 Laser Acrylic Wood Cutter 6040 6090 1080 Engraving Cutting Machine

TWOTREES China Manufacturer OEM DIODE Co2 Desktop Cutter and Engraver Marking Fiber Laser Engraving Cutting Machines Price

10W CNC Laser Engraver Cutter Machine Working Area Precise Diode Laser Engraving Wood Metal Glass Leather Large 400mm X 400mm

co2 cloth fabric textile laser cutter cutting machine

Promotion hot sale CO2 acrylic wood laser cutting machine jigsaw puzzle laser cutter EP1390 machine price

100w/120w/150w/180watts 1325 CNC Co2 Wood/Arcylic/Glass/Plastic Laser Engraving Cutting Engraver Cutters Machines Price

Laser carving machine 4060 engraving wood craft laser cutter

ATOMSTACK P7 M40 40W Low Price Laser Cutter Wood Metal Printer Marking Portable Laser Engraving Machine

FOCUS Cnc Laser Cutter Price 4060 Baseball-Bat-Laser-Engraving-Machine Wood Engraving Machine Laser

Bingyan 80W 100W 130W Laser Cutter 3040 4060 9060 1390 CNC Acrylic MDF Wood CO2 laser engraving machine price

CE approval wood acrylic laser cutter 100w 150w CO2 6090 1390 laser cutting machine price

150w 200w Pemotong Laser Cortador Laser Acrylic Wood Plywood Cutter 1325 Cnc Sheet Metal Laser Cutting Machine Price

2024 New Laser Cutting Machine Price Laser Cutter

JQ 1325 1530 CO2 Laser Cutting Machine For Acrylic Wood Laser Cutter Price 100w 150w CO2 Laser Engraving And Cutting Machine

cnc laser 6040 9060 plexiglass wood glass laser engraver 80w 100w co2 laser cutter

ATOMSTACK A10 S10 X7 Pro 50w Cheap Price Mini CNC Cutter Router Printer Aluminium Laser Cutting Engraver Acrylic Wood Machines

2021 Master 2S pius 40w NEJE Laser Wood Machine Price Portable Router Engraving Cutter With 15w Input

Large size laser cutter /CNC co2 laser cutting machine price for wood,fabric ,leather,cloth 130*250cm

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4