큰 원자로 만드는 양 900 ml/h 버섯 가습기 물 1.7 Mhz 변형기 3 맨 위 초음파 안개 제작자 Fogger

배송 준비 완료

₩69,471 - ₩79,197

최소 주문량: 1 개

조각 당 선박: ₩6,948

60W 40khz 힘 운전사 널 110V ac를 가진 초음파 청소 변형기 세탁기술자는 물을 위한 노란 초음파 변형기를 제공했습니다

₩11,116 - ₩20,842

최소 주문량: 1 개

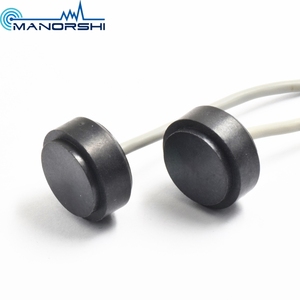

초음파 교류 미터에 이동 시간 결박 Tds-100F 의 시리즈 젖은 변형기 온도 감지기는 폐수를 분리했습니다

배송 준비 완료

₩215,360 - ₩270,937

최소 주문량: 5 유닛

조각 당 선박: ₩13,714

상위 카테고리

초음파 변환기 물 정보

축하를 할 때 참석하는 회사도 중요하지만 파티가 열리는 눈부신 환경도 중요합니다! 적절한 장식은 고객이 장소에서 완벽한 파티 분위기를 조성하는 데 도움이 될 수 있습니다. Alibaba.com의 도매상은 고객이 좋아하는 것을 찾을 수 있도록 초음파 변환기 물의 방대한 선택을 제공합니다.

{ keyword} 범위에서 파티 조명, 화환, 깃발 천, 색종이 조각, 풍선을 비롯한 다양한 전통 장식을 찾을 수 있습니다. 게스트에게 깊은 인상을 남기고 싶은 호스트는 게스트가 소셜 미디어에서 공유할 기억에 남는 사진을 찍을 수 있는 멋진 배경을 만들고 싶을 수 있습니다. 반면에 파티가 테마라면 데코레이션은 손님이 자신에게 적합하다고 느끼고 캐릭터를 플레이할 수 있는 적절한 환경을 조성하여 파티를 더 즐겁게 만드는 데 도움이 될 수 있습니다.

The 초음파 변환기 물 제품군은 색상, 디자인 및 가격이 매우 다양합니다. 개인적인 느낌을 원하는 고객은 개인화된 장식을 고려할 수 있으며 예산에 맞는 호스트를 위한 경제적인 옵션이 많이 있습니다. 간편함과 실용성을 원하는 고객을 위한 풀 파티 키트도 있습니다. 실내든 실외든, 정교하든 경제적이든 모든 장소와 축하 행사가 Alibaba.com에서 제공되는 초음파 변환기 물의 혜택을 받을 것이라는 데는 의심의 여지가 없습니다.