Popular in your industry

Top categories

About tool presetter

Understanding Tool Presetters

Tool presetters are essential devices in the realm of machining, designed to accurately measure the geometry of cutting tools. These instruments are pivotal for optimizing the precision and efficiency of CNC (Computer Numerical Control) machines. By ensuring tools are set to exact parameters, tool presetters contribute to the consistency and quality of manufactured parts.

Types and Applications

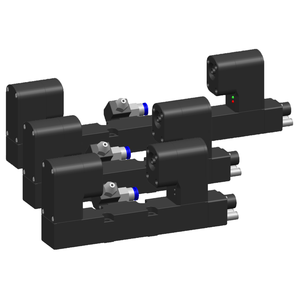

There are various types of tool presetters catering to diverse machining requirements. Some are simple, manual devices suitable for small-scale operations, while others are sophisticated, featuring digital readouts and automated adjustments for high-volume production environments. The application of these devices spans across industries such as automotive, aerospace, and metal fabrication, where precision tooling is critical.

Features and Materials

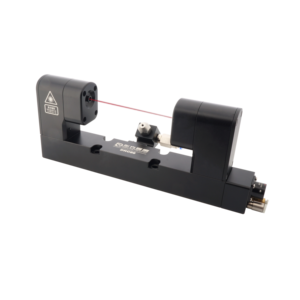

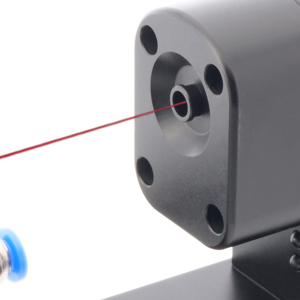

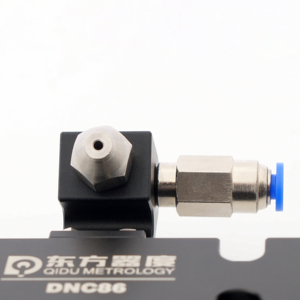

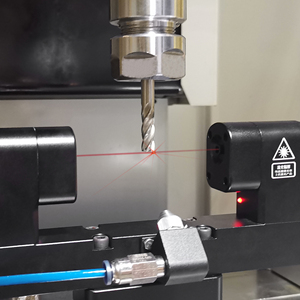

A tool presetter typically boasts a robust construction, often made from cast or mild steel to resist wear and torsion. Advanced models may include features like laser measurement systems, capable of handling various materials like glass, metal, and plastic with precision. The integration of dust collection units and protective cabinets are additional features that maintain the cleanliness of the workspace and ensure operator safety.

Advantages of Precision Tool Setting

Utilizing a tool presetter brings forth numerous advantages, such as reducing machine downtime by allowing offline tool setting and enhancing the lifespan of cutting tools through precise measurements. Moreover, the consistency in tool setting translates to uniform product quality, which is paramount in competitive manufacturing sectors.

Compliance and Safety

Manufacturers of tool presetters adhere to stringent ISO standards to ensure the safety and effectiveness of their products. These standards are a testament to the reliability of the equipment in maintaining workplace safety and delivering consistent performance in demanding industrial settings.

Choosing the Right Tool Presetter

Selecting the appropriate tool presetter for your needs involves considering the specific requirements of your printing machinery and the materials you work with. Whether for intricate engraving or robust cutting tasks, the right tool presetter can significantly enhance the operational efficiency of your CNC machines.