Qt4-15B Grote Capaciteit Volautomatische Blok Maken Machine Voor Straatstenen, Massieve Bakstenen & Blokken, Holle Blokken Machine

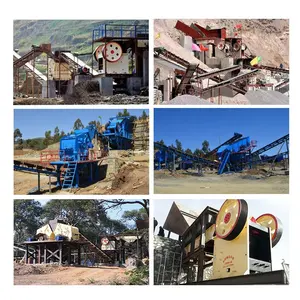

Draagbare Mobiele Hamerveer Kegel Steen Impact Crusher Zand Plant Productielijn Kaak Crawler Station Rock Machine Verpletteren

Bouwplaats Fabriek Verkoop Bakstenen Muur Cement Sproeier Machine Betonverf Mortel Gips Spuitmachines

Fabriek Directe Verkoop Pe 150*250 Mini Mobiele Kalksteen Steen Kaakbreker Machine Met Trilscherm

Qt4-26 Baksteenmachine Die Semi-Automatische Machines Voor Kleine Bedrijven Maakt

Handmatige Semi Automatische Elkaar Grijpende Hourdis Smart Habiterra Bestrating Hollow Cement Beton Blok Maken Machine Voor Beton Blok

QT4-25D Hoge Kwaliteit Volautomatische Beton Cement Hol Blok Baksteen Interlock Bestrating Making Machine Prijs In India

Volautomatische Beton Cement Bestrating Leggen Road Zand Holle Baksteen Maker Blok Maken Machine Prijs Voor Verkoop

Ds QTJ4-40 In Elkaar Grijpende Blok Betonblok Bestrating Baksteenmachine Prijs

Volautomatische Betonblok In Elkaar Grijpende Massieve Vliegas Bakstenen Fabriek Tuin Baksteen Maken Machines

QT8-15 Volautomatische Hydraulische In Elkaar Grijpende Betonblokmachine Gebruikte Machine Voor Het Maken Van Cement Holle Bakstenen Machine

Giantlin QT4-24 semi automatische cement hol blok making machine

QT40-2 Semi Automatische Beton Cement Machines Maken Holle Massief Blok Bakstenen Baksteen Making Machine Voor Verkoop

Automatische Cement Baksteen Maken Machines Betonblok Machine Voor Verkoop Bouwmateriaal Machines QT4-15 Spanje Producten 3500

QT4-18 Volautomatische Hydraulische Cement Blok Maken Machine Betonbestrating Blok Machine Trottensteen Holle Blok Machine Prijs

QT4-40 Hoge Efficiënte Holle Baksteen Machine Handleiding Blok Maken Machine

QT4-26 Semi-Auto Fabriek Verkoop Goedkope Prijs Hoge Kwaliteit Blok Maken Machine

Bakstenen Bestrating Machine Beton Holle Blokken Prijs In De Filipijnen Automatische Baksteenmachine Bestrating Blok Machine

China Fabriek Leveren Blok Maken Machine QT4-15 In Elkaar Grijpende Baksteen Making Machine

QTJ4-30 Handleiding Beton Hol Blok Baksteen Making Machine Prijs In Bangladesh

Handmatige Semi-Automatische In Elkaar Grijpende Hourdis Slimme Bestrating Holle Cement Betonblokmachine Voor Betonblok

Plastic Recycle Bricks Making Machine QT10-15F Bestrating Glas Mold Blok Making Machine Hydraulische Elkaar Grijpende Blok Machine

Hete Verkoop Kleinschalige Veel Gebruikte Handmatige Legblok Beton Holle Massief Bestrating Baksteen Maken Machine China Blok Maken Machine

Beste Prijs Hydraulische Interlock Baksteen Mal Grijpende Blok Bestrating Bodem Klei Grijpende Baksteen Making Machine

Qt4-15 Hydraulische Blok Machine Automatische Vliegas Baksteen En Betonmolen Blok Maken Machine

Xcmg Fabrikant Xz35a Bestrating Blok Betonblokken Maken Machine Met Een Goede Prijs

QMY4-30 Handmatige Mobiele Baksteenmachine Betoncementblokken Maken Machines Om Steen Massief Holle Bakstenen Bestrating Machine Te Maken

Aichen Laagste Prijs Mexico Fabriek Directe Baksteen/Blok Maken Machines Met Hopper

QTJ4-25 Holle Baksteen Betonblok Brandende Gratis Baksteen Making Machine Prijs In Indonesië

Gebruikte Automatische Baksteenmachines Betonblok Maken Machine Kleine Mobiele Baksteenblokmachine

Automatische Machines Voor Het Maken Van Stenen Holle Blokken Tegels Voor Kleine Bedrijven Betonnen Kleivloer Prijs Bedrijfsidee QT4-25

QMR2-40 Handmatige Kleine Project Klei Modder Baksteen Maker Maker Machine

Cementstenen En Baksteenmachine Automatische QMR2-45 Kleine Baksteenmachine

Qt4-35 automatische hydraulische kleur bestrating baksteen making machine grijpende blok maken machine te koop

Qt4-40 Cement Blok Maken Machine Molding Line Automatische Beton Baksteen Maken Machine Met Aangepaste Mallen

Factory Direct Sale Stationary Cement Brick Maker Machines in India Hollow Concrete

Semi-Automatische Vliegas Baksteen Maken Machine Prijs Bestrating Blok Machine 4-25

Blocktech QT8-15 Holle Volautomatische Hydraulische Betonblok QT8-15 Hoge Kwaliteit Bestrating Machine Prijs

Hoge Kwaliteit 2.5M Baan Plastic Cement Betonnen Weg Bestrating Rubber Bestrating Plastic Spoor Rubber Bestrating Machine

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4