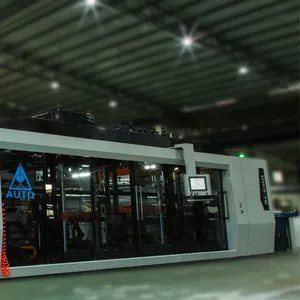

Introduction to Styrofoam Container Production Equipment

Styrofoam, a material known for its lightweight and insulating properties, is widely used in various industries for packaging and protection. The styrofoam container making machine stands at the core of this production, enabling the creation of containers that serve numerous purposes from food preservation to electronics packaging. This machinery is designed to meet the diverse needs of manufacturers, offering a reliable solution for producing high-volume, cost-effective packaging materials.

Types and Applications

The versatility of styrofoam packaging machines is evident in their ability to produce a range of container sizes and shapes. These machines are utilized in sectors such as pharmaceuticals, food and beverage, and consumer electronics, where protective packaging is crucial. The end products are essential for the safe transport of fragile items, providing cushioning and thermal insulation, which is particularly beneficial for temperature-sensitive goods.

Features and Performance

A foam container machine is engineered with features that ensure efficiency and durability. The machines are equipped with advanced control systems for precision manufacturing, and their robust design allows for continuous operation, essential for meeting industrial demands. With a focus on sustainability, many machines now incorporate energy-saving technologies, reducing the overall environmental footprint of the production process.

Material Advantages

Styrofoam's unique cellular structure, produced by a foam container manufacturing machine, offers significant advantages. It is capable of supporting many times its own weight, which is why it is a preferred choice for protective packaging. The material's insulation properties also make it ideal for transporting perishable goods, as it helps maintain temperature consistency, reducing the risk of spoilage and contamination.

Environmental Considerations

Modern styrofoam forming machines are designed with environmental considerations in mind. The production process aims to minimize waste, and the machines often feature recyclability options, allowing manufacturers to produce eco-friendlier products. Additionally, the inert nature of styrofoam means it does not react with the contents it holds, maintaining the integrity of the product without altering taste or odor.

Choosing the Right Machine

Selecting the appropriate styrofoam container equipment is crucial for businesses looking to enhance their packaging processes. Factors such as production capacity, container size, and specific industry requirements play a significant role in the decision-making process. While Alibaba.com does not endorse any particular product, the platform offers a diverse range of machinery options from various suppliers to meet the needs of different businesses.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4