Máy Cán Màng Tự Động DMAIS Tốc Độ Cao Máy Cán Màng Nóng Và Lạnh

1.000,00 US$ - 1.200,00 US$

Min Order: 1 Bộ

CNSupplier

A4 có khả năng ảnh máy đúc ảnh thông qua các máy đúc văn phòng máy cán ép nhiệt

8,95 US$ - 9,51 US$

Min Order: 800 Cái

CNSupplier

Huệ Châu yudu 216x303mm 75mic 75u A4 kích cỡ của vật nuôi nhiệt Ép phim

1,46 US$ - 1,54 US$

Min Order: 800 Hộp

Material: Pet

Feature: Moisture Proof

Processing Type: Multiple Extrusion

CNSupplier

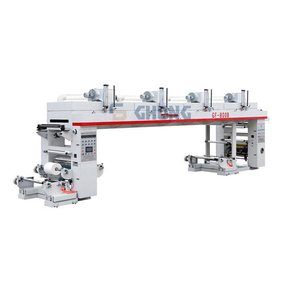

Máy cán sáo 5 lớp với chức năng thiết lập nhanh

98.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Plastic

Packaging Type: Film

Driven Type: Mechanical

CNSupplier

12 yrs

Tự động cuộn để cuộn cán Máy cán máy móc xe Sticker Laminator

650,00 US$ - 1.300,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Wood

Packaging Type: Cartons

Driven Type: Electric

CNSupplier

dung môi miễn phí máy cándệt khô cán máymáy cán dung môimáy cán dung môimáy cán dung môidung môi miễn phí máy cánmáy cán khô caomáy cán chân không tự độngkhô cán máy nhà máymáy cán chân không tốt nhấtphim khô cán máy1100 khô cán máymàn hình lcd chân không cán máymáy cán khô mớimáy cán màng chân không

High Speed Solvent Base Dry Laminating machine

20.000,00 US$ - 30.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Paper

Packaging Type: Bottles

Driven Type: Hydraulic

CNSupplier

Máy Cán Khô Cơ Sở Dung Môi Chất Lượng Cao

28.000,00 US$ - 29.800,00 US$

Min Order: 1 Cái

Type: Laminating Machine

Packaging Material: Paper

Packaging Type: Film

Driven Type: Electric

CNSupplier

6 yrs

GF-D PLC Kiểm Soát Phim Khô Dung Môi Dựa Trên Máy Cán

35.000,00 US$ - 45.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Paper

Packaging Type: Barrel

Driven Type: Electric

CNSupplier

11 yrs

BOPP PET PE Metalized Phim Giấy Nhôm Lá Tốc Độ Cao Phim Nhựa CuộN Dung Môi Keo Phủ Khô Máy Cán

19.000,00 US$ - 35.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Plastic

Packaging Type: Film

Driven Type: Electric

CNSupplier

5 yrs

Máy Cán Khô Cơ Sở Dung Môi Tốc Độ Cao Cho Bopp Pet Nhôm

15.000,00 US$ - 50.000,00 US$

Min Order: 1 Bộ

Warranty: 1 Year

CNSupplier

Máy Cán Màng Dung Môi Loại Khô Máy Cán Màng Khô

41.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Plastic

Packaging Type: Film

Driven Type: Electric

CNSupplier

Nhựa Cuộn cán PP PE OPP GIẤY Khô phim laminator dung môi Giá máy

20.000,00 US$ - 120.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Plastic

Packaging Type: Film

Driven Type: Electric

CNSupplier

12 yrs

HTL-D hanplas dung môi dựa trên phim máy cán khô loại phim Laminator khô máy cán

45.000,00 US$ - 60.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

CNSupplier

ZRGF-A tự động dung môi dựa trên bộ phim nhựa giấy khô cán máy ép giá

27.000,00 US$ - 28.500,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Paper

Packaging Type: Film

Driven Type: Electric

CNSupplier

6 yrs

Máy Cán Màng Loại Khô Dựa Trên Dung Môi Tự Động

20.000,00 US$ - 70.000,00 US$

Min Order: 1 Bộ

Warranty: 1 Year

CNSupplier

4 yrs

Máy cán khô keo dung môi và nước màu xanh điện cung cấp xiehe nóng chảy keo Pur Máy cán 10 m * 1.5m * 2.3 m

19.500,00 US$ - 20.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Metal

Driven Type: Electric

CNSupplier

4 yrs

Máy Cán Màng Dung Môi Cỡ Lớn 1500Mm Máy Ép Màng Khô Máy Ép Khô

26.500,00 US$ - 27.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Plastic

Packaging Type: Film

Driven Type: Electric

CNSupplier

2 yrs

Giá thấp nhất nhà máy sản xuất Báo Chí nóng cho ván ép và khô loại dung môi dựa trên Máy cán

550,00 US$ - 600,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Wood

Packaging Type: Cartons

Driven Type: Electric

CNSupplier

2 yrs

Dung môi dựa trên phim máy cán khô loại phim Laminator khô máy cán

52.777,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Metal

Packaging Type: Barrel

Driven Type: Mechanical

CNSupplier

1 yrs

Khô Loại cán máy 150 tốc độ

27.000,00 US$ - 32.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Plastic

Packaging Type: Film

Driven Type: Pneumatic

CNSupplier

12 yrs

Mới khô loại tốc độ cao Máy cán được sử dụng cho Bopp

8.000,00 US$ - 11.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Paper

Packaging Type: Film

Driven Type: Electric

CNSupplier

4 yrs

Giấy Laminator A3 A4 tự động tông cán máy tự động cho ăn và phá vỡ ra khỏi nhiệt cán máy

998,00 US$ - 1.300,00 US$

Min Order: 1 Bộ

CNSupplier

Giấy Laminator A3 A4 tự động tông cán máy tự động cho ăn và phá vỡ ra khỏi nhiệt cán máy

2.250,00 US$ - 2.350,00 US$

Min Order: 1 Bộ

CNSupplier

Máy Phủ Màng OPP PE Cán Khô Giấy Nhôm PVC PP Tốc Độ Cao

Sẵn sàng vận chuyển

10.000,00 US$

Min Order: 1 Bộ

Shipping per piece: 0,00 US$

Type: Laminating Machine

Packaging Material: Plastic

Packaging Type: Film

Driven Type: Electric

CNSupplier

4 yrs

150 M/phút CuộN Để Cuộn Dung Môi Khô Phim Laminating Máy

25.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Plastic

Packaging Type: Case

Driven Type: Electric

CNSupplier

PVC Bopp gói thực phẩm giấy nhôm lá nhựa cơ sở dung môi Máy cán khô

180.000,00 US$

Min Order: 1 Cái

Type: Laminating Machine

Packaging Material: Paper

Packaging Type: Film

Driven Type: Electric

CNSupplier

Thiết kế mới gf1100q tốc độ cao dung môi dựa trên khô loại cán Máy ép 160 m/phút

33.800,00 US$ - 33.900,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Paper

Packaging Type: Film

Driven Type: Electric

CNSupplier

6 yrs

Dung môi dựa trên phim máy cán khô loại phim Laminator khô máy cán

19.000,00 US$ - 35.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Plastic

Packaging Type: Film

Driven Type: Electric

CNSupplier

5 yrs

Sử Dụng Dung Môi Khô Laminating Machine Nước Dựa Keo Cho Khô Cán Kính Khô Khô

28.358,20 US$ - 29.850,70 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Metal

Packaging Type: Film

Driven Type: Electric

CNSupplier

2 yrs

Dung môi dựa trên phim máy cán khô loại phim Laminator khô máy cán

52.777,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Metal

Packaging Type: Barrel

Driven Type: Mechanical

CNSupplier

1 yrs

HTL-D hanplas tự động dung môi dựa khô loại phim Máy cán

45.000,00 US$ - 60.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

CNSupplier

Ôn Châu Jiamao Kinh Tế Loại Nhôm Phim Với Pe Phim Khô Phương Pháp Tốc Độ Cao Máy Cán

15.000,00 US$ - 50.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Paper

Packaging Type: Film

Driven Type: Electric

CNSupplier

12 yrs

Tốc độ cao khô máy cán cho bộ phim nhựa/giấy/nhôm lá mỏng nhà máy giá điện cung cấp PLC hoàn toàn tự động

Sẵn sàng vận chuyển

11.000,00 US$

Min Order: 1 Bộ

Shipping per piece: 0,00 US$

Type: Laminating Machine

Packaging Material: Plastic

Packaging Type: Film

Driven Type: Electric

CNSupplier

4 yrs

H351 giá cả phải chăng solventless cán máy cho khô cán

500,00 US$ - 600,00 US$

Min Order: 5 Bộ

Type: Laminating Machine

Packaging Material: Paper

Packaging Type: Film

Driven Type: Electric

CNSupplier

2 yrs

Tự động dựa trên dung môi khô loại phim Laminator Máy Điều kiện Mới với lõi thành phần động cơ nhựa gỗ bao bì giấy

8.000,00 US$ - 11.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Paper

Packaging Type: Film

Driven Type: Electric

CNSupplier

4 yrs

Tốc Độ Cao PVC Bopp Gói Thực Phẩm Giấy Nhôm Lá Nhựa Phim Dung Môi Cơ Sở Khô Máy Cán

179.000,00 US$

Min Order: 1 Cái

Type: Laminating Machine

Packaging Material: Paper

Packaging Type: Bottles

Driven Type: Electric

CNSupplier

Máy Cán Màng Dung Môi Loại Khô Máy Cán Màng Khô

20.000,00 US$ - 30.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Plastic

Packaging Type: Case

Driven Type: Electric

CNSupplier

Gf1100b tự động dung môi khô loại Bopp Pet CPP PE lá cán máy

95.800,00 US$ - 95.900,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Paper

Packaging Type: Film

Driven Type: Electric

CNSupplier

6 yrs

Dung Môi Dựa Trên Máy Ép

19.000,00 US$ - 35.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

Packaging Material: Plastic

Packaging Type: Film

Driven Type: Electric

CNSupplier

5 yrs

HTL-200W tốc độ cao sữa chua bao gồm ba lớp phim dung môi ít máy cán

95.000,00 US$ - 100.000,00 US$

Min Order: 1 Bộ

Type: Laminating Machine

CNSupplier

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4