About products and suppliers

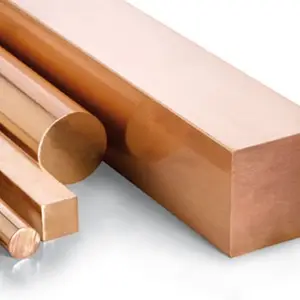

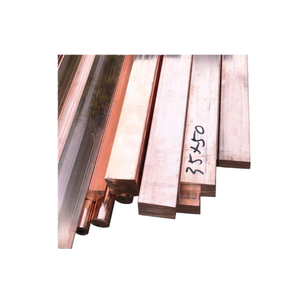

Ngày nay, thanh đồng rắn không còn là điều mới mẻ đối với những người bình thường và không còn bị coi là điều cấm kỵ khi sử dụng. Nếu bạn đang tìm kiếm niềm vui áp chót đó, bạn phải kiểm tra sự bao la. Bộ sưu tập thanh đồng rắn tại Alibaba.com. Những gợi cảm và cong. thanh đồng rắn đáng giá từng xu và chắc chắn làm cho đêm đó trở nên đặc biệt đối với bạn. Những con búp bê này có ngoại hình giống như thật, bắt đầu từ tóc đến ngón chân theo mọi nghĩa.

Cho dù bạn là một người cô đơn đang tìm kiếm một người bạn đời như cuộc sống hay một cặp vợ chồng muốn thêm gia vị cho cuộc sống của họ, bạn đều có thể sử dụng chúng . thanh đồng rắn để đốt cháy ngọn lửa đó. Những ngoạn mục. thanh đồng rắn có thể tùy chỉnh theo mong đợi của bạn. Những điều tuyệt vời. thanh đồng rắn có sẵn ở cả phiên bản dành cho nam và nữ và được làm từ silicone cấp y tế để sử dụng an toàn. Hãy sở hữu ngay bây giờ và tận hưởng một đêm đam mê và cháy bỏng.

Alibaba.com cung cấp những điều tuyệt vời này. thanh đồng rắn ở mọi hình dạng cơ thể, kích thước và sắc tộc. Dù yêu cầu của bạn đối với. thanh đồng rắn, bạn có thể tải tất cả chúng trên trang web. Những cái này. thanh đồng rắn được tạo hình bởi những người thợ thủ công giỏi nhất và mọi chi tiết phức tạp đều được kiểm tra kỹ lưỡng. Những con búp bê này có mắt, tóc, móng tay và tất cả các bộ phận cơ thể khác tương tự như người thật.

Alibaba.com cung cấp nhiều loại. thanh đồng rắn có thể giúp bạn mua các sản phẩm phù hợp với ngân sách và các yêu cầu khác của bạn. Các sản phẩm này an toàn để sử dụng, được chứng nhận và thân thiện với môi trường trong tự nhiên. Đơn đặt hàng OEM có sẵn trên các sản phẩm này.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4