Popular in your industry

Related Searches:

Top categories

About smartphone mould

Exploring the Versatility of Smartphone Moulds

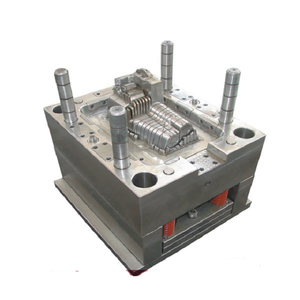

The realm of smartphone manufacturing is ever-evolving, with smartphone moulds playing a pivotal role in the production process. These moulds are essential for shaping the intricate components that comprise modern mobile devices. As a critical category within the manufacturing industry, smartphone moulds come in various designs to cater to the diverse needs of smartphone production.

Types and Applications of Smartphone Moulds

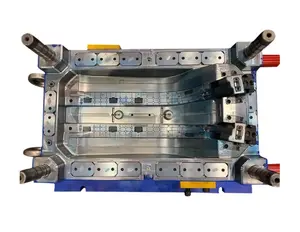

Smartphone moulds are not one-size-fits-all; they are tailored to meet specific manufacturing requirements. From injection moulding techniques for small, complex parts to larger designs for aesthetic enhancements, these moulds are integral in creating both functional and decorative elements of smartphones. The application of these moulds extends to forming precise cutouts for cameras, buttons, and ports, ensuring that each smartphone component fits seamlessly into its designated space.

Material Considerations in Mould Design

Selecting the appropriate material for a mould design is crucial. Options range from durable iron to advanced composites, each offering distinct advantages in terms of longevity and precision. The choice of material impacts the mould's performance and the quality of the final smartphone components. Manufacturers must consider factors such as heat resistance and material strength when selecting a mould material to ensure it meets the demands of smartphone production.

Features and Advantages of Quality Moulds

A well-crafted smartphone mould is characterized by its ability to produce consistent, high-fidelity parts. The advantage of utilizing such moulds includes increased efficiency in the manufacturing process and the potential for cost savings through standardized components. For instance, standardizing elements like lift bars and clamp slots can simplify the production process for multiple moulded products. Additionally, the precision of a quality mould ensures that each smartphone component meets stringent industry standards.

Optimizing Production with Smartphone Moulds

In the pursuit of operational excellence, the integration of smartphone moulding into the production line can be a game-changer. By working closely with moulding experts, manufacturers can refine their moulds through rigorous testing and sampling, ensuring that the final product aligns with their exact specifications. This optimization process is crucial for maintaining the integrity of the smartphone's design and functionality.

Choosing the Right Mould for Your Needs

Navigating the selection of a smartphone mould on Alibaba.com is streamlined, providing access to a wide array of options to suit various manufacturing needs. Without endorsing any specific service or guarantee, the platform facilitates connections between buyers and suppliers, offering a comprehensive overview of available moulds. By leveraging the detailed information provided, buyers can make informed decisions to find the mould that aligns with their production requirements.