Top-Kategorien

Computer-Hardware und -Software

Kabel und häufig verwendetes Zubehör

Projektoren und Präsentationsgeräte

Gebrauchte Elektronik

Sonstige Unterhaltungselektronik

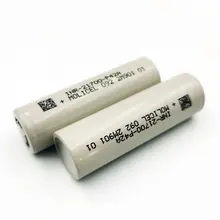

Ladegeräte, Batterien und Stromversorgungen

Mobiltelefon und Zubehör

Videospiele und Zubehör

Tragbares Audio, Video und Zubehör

Kamera, Foto und Zubehör

Fernsehen, Heim-Audio, Video und Zubehör

Elektronische Publikationen

VR-, AR- und MR-Hardware und -Software

Ohrhörer und Kopfhörer und Zubehör

Lautsprecher und Zubehör

Intelligente Elektronik

About products and suppliers

Alibaba.com bietet 15505 welle s Produkte an.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4