Popular in your industry

Top categories

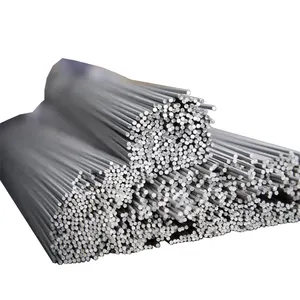

About sale heavy steel

Alibaba.com features sale heavy steel of all specifications for all uses at great prices. sale heavy steel also known as reinforcement steel are used to strengthen concrete. They do this by increasing the tensile strength of concrete as in reinforced concrete. Carbon steels are the most common type of sale heavy steel, but other kinds like stainless steel and composite bars are also in use. Physically, concrete and steel have similar thermal expansiveness and so they work well when combined into a strong all-weather material.

sale heavy steel are available in all grades and specifications on Alibaba.com. Choose the properties of your purchase like diameter, hot-rolled, cold-rolled, corrugated, and more. sale heavy steel are stronger than galvanized steel. They prevent cracks in the concrete. When used with concrete for construction, thinner concrete will do the job. sale heavy steel are extremely long-lasting, cost-effective, and responsive.

sale heavy steel prove useful in enhancing the functionality of a number of commercial enterprises. These include airports, agriculture, fencing, infrastructure, and concrete slabs. When you buy sale heavy steel compare from the various international sellers and narrow your choice based on price, quality, and reviews of previous customers.

At Alibaba.com you can go through the entire span of sale heavy steel offers and match your requirements at budget-friendly prices. You can buy samples before the actual purchase. Send instant messages to suppliers, and receive a fast response. Here you get good deals, easy and secured payment, fast delivery, and shop with trust.