Popular in your industry

Related Searches:

Top categories

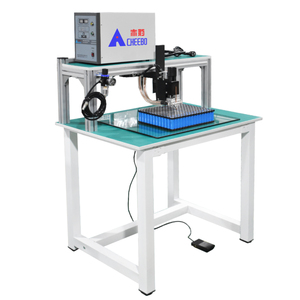

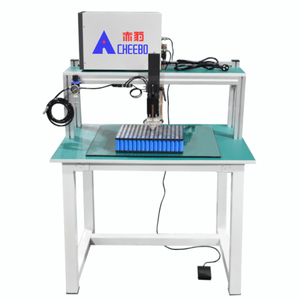

About resistance welding machine

What is Welding Machine For Resistance Applications

Welding machines for resistance applications are specialized equipment designed for joining materials through the application of heat and pressure. These machines are commonly used across various industrial sectors, including automotive, construction, electronics, and even in the manufacturing of household appliances. The primary principle behind their operation is the creation of a high-temperature electrical circuit that passes through the material to be welded, generating localized heat at the interface which softens the material, allowing for fusion and joining.

These machines utilize the electrical resistance heating method, where an electric current is passed through a resistive material, typically a metal, to produce heat. This heat is then concentrated at the point of contact between the materials to facilitate the welding process. The amount of heat generated is directly proportional to the electrical current and the resistance of the material it's passing through. Therefore, by controlling these variables, welders can adjust the temperature and duration of the heat treatment to ensure a precise and reliable weld.

Welding machines for resistance applications come in various types and configurations, each suited to specific welding requirements—be it spot welding for localized high-precision work, or seam welding for airtight and leak-free joins. They are designed for both manual and automated operations, providing a wide range of options for professionals to choose from based on the specific demands of their projects.

Types of Welding Machines for Resistance Applications

The world of resistance welding offers a variety of machines tailored to meet specific needs across different industries. Here's an overview of some common types:

-

Spot Welding Machine: This type of machine is primarily used for joining thin metal sheets. It works by passing an electric current through the sheets to create resistance at the points where the metal touches. Spot welds are commonly seen in car manufacturing and in the production of steel drums.

-

Seam Welding Machine: Seam welders are designed to join two pieces of metal along a linear seam. The welding wheel and the material being joined are the main contact points. This type of machine is commonly used in the manufacturing of tubes, pipes, and similar products.

-

Flash Butt Welding Machine: Flash butt welders use an electric current to heat the ends of two pieces of metal to a high temperature. The pieces are then pressed together to form a weld. This method is often chosen for its strength and reliability in critical applications like aerospace.

-

Resistance Spot Welding Machine: Also known as resistance spot welders, these machines are used to make 'finned' or 'penny-shaped' welds. They are ideal for joining two or more sheets of metal where a strong but small weld is required. These are often found in HVAC (heating, ventilation, and air conditioning) industries.

How to choose Welding Machine For Resistance Applications

Selecting the right welding machine for your business involves considering several factors:

-

Power Requirements: Ensure that the machine is compatible with your facility's power supply. Most industrial machines operate on 220V or 380V, but some may be adjustable or dual voltage for different job sites.

-

Material Compatibility: Match the machine with the type of material you will be working with most frequently. For example, if you primarily work with low carbon steel, a MIG welder might be your best choice.

-

Thickness of Materials: Consider the thicknesses of the materials you will be welding. TIG and plasma welders are better suited for thinner materials that require precise heat control.

-

Required Mobility: If your work involves moving between sites or locations within a facility, select a machine that is easily transportable like an engine-driven welder or a portable spot welder.

-

Quality of Weld: Look for machines that have reliability features such as overheat protection or automatic shut-off functions which ensure longevity and safety during operation.

Remember that when purchasing on Alibaba.com, you have access to a vast array of suppliers offering different types of welding machines with various specifications tailored to different applications.

About Welding Machine For Resistance Applications on Alibaba.com

For businesses seeking reliable resistance welding solutions, Alibaba.com stands out as a global marketplace connecting buyers with an extensive network of suppliers offering a wide array of welding machines suitable for various industrial applications. Whether you're involved in manufacturing plants, construction projects or require customized solutions for unique requirements, Alibaba.com facilitates access to a diverse selection of welding equipment that meets commercial needs without compromising on quality.

Alibaba.com's platform simplifies the sourcing process with user-friendly search capabilities allowing you to find machinery that fits your specific criteria such as voltage requirements, machinery test reports provided when available, and key selling points like high productivity or ease of operation. Additionally, Trade Assurance service adds a layer of protection to your transactions ensuring that your investment is safeguarded until delivery is fulfilled.

Businesses worldwide trust Alibaba.com not only for its vast product offerings but also for its commitment to supporting trade with services that streamline procurement processes. With features accommodating mobile purchases and communication in local languages alongside order handling and delivery services, Alibaba.com exemplifies how online marketplaces can make international sourcing efficient and convenient regardless of your industry focus or geographic location.

Common FAQs for Welding Machine For Resistance Applications

What types of resistance are welding machines suitable for?

Resistance welding machines are suitable for all types of resistance welding, including spot welding, projection welding, butt welding, and seam welding. They are commonly used in various industries for joining different materials such as steel and copper.

Can resistance welding machines be used for heavy-duty applications?

Yes, there are resistance welding machines designed for heavy-duty applications that involve high-strength materials or demanding production environments. It's important to select a welder with the appropriate specifications for the materials and applications required.

What materials can be welded with resistance welding machines?

Resistance welding machines are versatile and can be used to weld a wide range of materials including steels, copper, aluminum, and their alloys. The specific material that can be welded will depend on the machine's settings and capabilities.

Are portable resistance welding machines available?

Yes, portable resistance welding machines are available and are especially useful for applications that require mobility or where a fixed power source is not convenient.

How do I determine the right type of resistance welding machine for my business needs?

To determine the right type of resistance welding machine for your business, consider the material types you will be welding, the specific applications such as spot or seam welding, any additional features you may need (e.g., automatic feeding systems), and the portability of the equipment.

What should I look for in terms of after-sales support for a resistance welding machine?

Look for after-sales support such as video technical support, online or field maintenance and repair service, and engineers available to service machinery overseas. Availability of spare parts can also be an important factor if needed.

How does customization support work for resistance welding machines?

Customization support for resistance welding machines typically involves ODM (Original Design Manufacturing) or OBM (Original Brand Manufacturing) services where you can work with suppliers to develop products that meet your specific requirements.

What core components are essential in a resistance welding machine?

Essential core components in a resistance welding machine include the PLC (Programmable Logic Controller), motor, gearbox, pressure vessel, and key selling points like easy operation, competitive pricing, high productivity, and long service life.

Can resistance welding machines be integrated into existing production lines?

Yes, resistance welding machines can often be integrated into existing production lines provided they fit the space requirements and meet the electrical supply specifications of the facility.

What is the role of the PLC in a resistance welding machine?

The PLC (Programmable Logic Controller) in a resistance welding machine is crucial as it manages the welding process by controlling parameters such as welding current, time duration, and electrode pressure.

Are there environmentally friendly options available for resistance welding machines?

While the metal joining process itself may not be considered eco-friendly due to its energy consumption, there are options available that focus on energy efficiency and may use less consumable materials.

How do I ensure the quality of a used or refurbished resistance welding machine?

To ensure the quality of a used or refurbished resistance welding machine, you should inspect its condition through detailed photos or in person if possible. Additionally, check if there is any warranty or service history provided by the supplier.

Are there any key selling points I should highlight when selecting a resistance welding machine?

Key selling points when selecting a resistance welding machine include easy to operate features, competitive pricing, high productivity due to quick welding cycles, and long service life. Also consider factors like local service availability and potential after-sales support.

What safety precautions should be considered when operating a resistance welding machine?

Safety precautions when operating a resistance welding machine include wearing appropriate personal protective equipment (PPE), ensuring proper ventilation in the work area to prevent fumes or gases from accumulating, and following all manufacturer guidelines for safe operation.