Introduction to Pipe Inner Surface Sand Blasting Machines

Exploring the realm of industrial finishing and surface preparation, the pipe inner surface sand blasting machine stands as a pivotal category. These machines are engineered to meticulously clean and etch the interior surfaces of pipes, ensuring optimal adhesion for coatings and treatments. The technology is crucial for industries that demand high standards of surface cleanliness and roughness, such as oil and gas, water treatment, and construction.

Types and Configurations

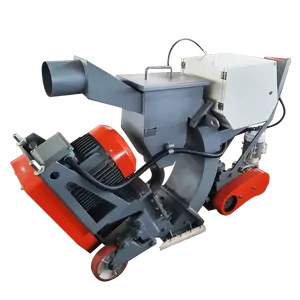

The versatility of pipe sandblasting equipment is reflected in its various types and configurations. From pneumatic to electric systems, each machine is designed to accommodate different pipe diameters and materials. Some are tailored for small-scale operations, while others are built for large industrial applications, ensuring a broad spectrum of solutions for diverse requirements.

Applications and Features

Internal pipe blasting tools are indispensable in applications where precision and efficiency are paramount. They are adept at removing rust, scale, and other contaminants, preparing pipe interiors for processes such as painting or coating. Key features often include adjustable pressure settings, various blast media compatibility, and ergonomic designs that facilitate ease of use and maintenance.

Materials and Advantages

Constructed from robust materials like reinforced steel or high-grade alloys, pipe surface treatment machines are built to withstand the rigors of industrial use. The advantages of using such equipment include a uniform treatment of the pipe's inner surface, increased longevity of the pipe post-treatment, and significant time savings compared to manual sandblasting methods.

Operational Considerations

When selecting a sand blasting machine for pipe cleaning, operational considerations such as the machine's compatibility with different types of abrasive materials, its energy consumption, and the ease of changing the blasting nozzles are crucial. These factors directly impact the efficiency and cost-effectiveness of the sandblasting process.

Environmental and Safety Features

Modern pipe inner surface sand blasting machines are designed with environmental and safety features in mind. Dust collection systems, noise reduction mechanisms, and safety interlocks are some of the integrated features that not only protect the operator but also minimize the environmental footprint of the sandblasting operation.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4