Popular en tu industria

Detector de oro para alimentos, máquina de inspección de metales, harina, aperitivo, pan, túnel, máquina de detección de metales, suministro directo de fábrica

Listo para enviar

$3,800.00 - $4,500.00

Pedido mínimo: 1 conjunto

Envío por pieza: $1,000.00

Fctroy TUV EN14604 Aprobado Batería de litio Sensor fotoeléctrico Detector de humo independiente

$4.75 - $5.45

Pedido mínimo: 1000 piezas

Venta al por mayor Mini 3 Años de Batería Portátil Co Alarma Detector de Monóxido de Carbono para Camping/Viajes

$5.41 - $5.97

Pedido mínimo: 1 pieza

Detector de llama ultravioleta a prueba de explosiones para caldera Industrial, Sensor UV IR Ultra rápido 40/40Ufl con sonda de controlador

$250.00 - $500.00

Pedido mínimo: 1 conjunto

HACCP de la industria de alimentos detector de metal adecuada para harina comida hecha

$3,260.00 - $4,460.00

Pedido mínimo: 1 conjunto

Detector de metales industrial Procesamiento de señal digital con configuración de aprendizaje automático

$3,600.00 - $4,000.00

Pedido mínimo: 1 conjunto

Sistema de Seguridad de haz láser infrarrojo, Detector de movimiento de bajo coste, gran oferta

$19.00 - $21.50

Pedido mínimo: 15 conjuntos

Granja al aire libre Multi Break Beam Sensor 4/6/8 haces 50m a 200m Photobeam Detector alarma perímetro alarma para valla

Listo para enviar

$23.00 - $29.00

Pedido mínimo: 200 unidades

Envío por pieza: $2.02

Detector de haz de luz antirrobo personalizado, fotorayo de alarma de viaje con perímetro

$115.00 - $130.00

Pedido mínimo: 10 pares

Tipo de frecuencia Photobeam Sensor Exterior Impermeable Sensor de haz infrarrojo Perímetro Alarma Valla Protección Detector de haz de seguridad

$28.10 - $29.40

Pedido mínimo: 2 pares

Alarma infrarroja activa con cable Detector de intrusión, Sensor de haz doble, cerca de barrera perimetral exterior de 20/30/60M para sistema de alarma GSM

$10.00 - $13.00

Pedido mínimo: 15 conjuntos

Búsquedas Relacionadas:

detector de fotos ingaasdetector de mineralesdetector de co independientedetector leldetector de materia extranjeradetector girardetector de porosidad vacacionaldetector de voc portátildetector fgdetector sensible de posicióndetector de co2 vocdetector noktadetector toshibadetector md5008detector de co visual

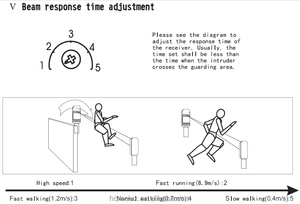

Sensor de fotohaz infrarrojo de SEGURIDAD, ALARMA, sensor, detector

$25.00 - $40.00

Pedido mínimo: 1 par

Alarma de seguridad de intrusión perimetral alimentado por batería inalámbrica solar Detector de haces fotoeléctricos

$60.00 - $90.00

Pedido mínimo: 100 piezas

Cable infrarrojo fotocélula rayo sensor para intruso sistema de alarma y el perímetro de seguridad

$15.80 - $16.90

Pedido mínimo: 100 conjuntos

100 eter 4 Frequrequigital Ired UAL nnfrared 2 Beam ensensor para ececurity larlarm

$11.00 - $14.00

Pedido mínimo: 100 piezas

Sensor automático de puerta corredera, Sensor de Fotocélula de puerta infrarroja

Listo para enviar

$4.90 - $7.50

Pedido mínimo: 1 pieza

Envío por pieza: $9.76

Categorías principales

Sobre photobeam detector

Alibaba.com ofrece los productos 18 detector fotobeam.