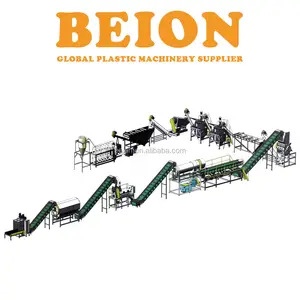

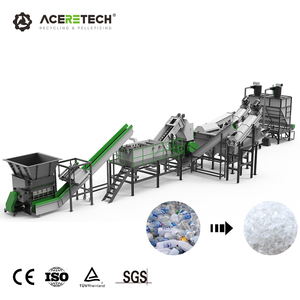

Truy cập vô số công suất cao, thành thạo và thông minh. máy móc tái chế vật nuôi tại Alibaba.com cho tất cả các loại quy trình làm sạch. Những cái này. máy móc tái chế vật nuôi có các phiên bản thủ công và tự động để làm sạch chính xác và được sử dụng rộng rãi để làm sạch các tài sản thương mại. Công nghệ được sử dụng để phát triển các sản phẩm này là chưa từng có với tất cả các tính năng mới nhất có trong các gói. Những cái này. máy móc tái chế vật nuôi bền và đi kèm với động cơ chạy điện hiệu quả trong việc làm sạch ngay cả những khu vực bẩn nhất.

The. máy móc tái chế vật nuôi cực kỳ đáng tin cậy và được coi là tốt vì không tiêu thụ điện quá mức, giúp tiết kiệm hóa đơn năng lượng của bạn. Những chiếc máy đa năng này rất thành thạo trong việc làm sạch tất cả các loại sàn nhà, ô tô, máy móc, và nhiều loại khác tùy thuộc vào mô hình bạn chọn. Bạn có thể chọn từ phổ biến nhất. máy móc tái chế vật nuôi kiểm tra các bài đánh giá của khách hàng và các tính năng có sẵn khi chúng hoạt động. Các thành phần cốt lõi trong số này. máy móc tái chế vật nuôi là PVC, mô tơ, động cơ, ổ trục và ống công suất cao để phun không khí hoặc nước.

Alibaba.com cung cấp nhiều loại sản phẩm ưu việt này. máy móc tái chế vật nuôi có sẵn ở các kích thước, hình dạng, màu sắc, tính năng và chất lượng vật liệu riêng biệt. Những phần nổi bật của. máy móc tái chế vật nuôi có sẵn ở các kiểu máy như máy sấy sàn, máy rửa xe, máy chà sàn, máy lọc DPF, máy tẩy cầm tay Rust Blast và nhiều loại máy riêng biệt khác. Những cái này. máy móc tái chế vật nuôi ứng biến các quy trình làm sạch bằng nước nóng khác nhau, quy trình thổi khí, quy trình làm sạch bằng nước mát, quy trình laser sợi quang và hơn thế nữa, để thực hiện các quy trình làm sạch tối ưu

Kiểm tra phạm vi khác nhau của. máy móc tái chế vật nuôi có thể phù hợp với yêu cầu của bạn. Các sản phẩm này được chứng nhận ISO, CE, ROHS và cũng có thể truy cập dưới dạng đơn đặt hàng OEM. Những sản phẩm này cũng có sẵn để đóng gói tùy chỉnh khi mua với số lượng lớn.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4