Popular in your industry

Top categories

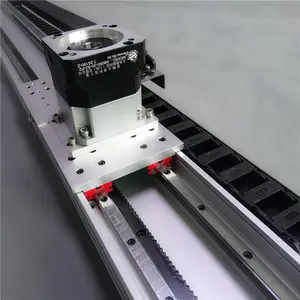

About linear rails

A linear rail is a vital component in machinery, designed to provide precise and smooth linear motion. It is a type of guide rail that serves as a track for linear bearings and rails, enabling them to move back and forth in a straight line. Linear rails find extensive use in various applications across industries such as manufacturing, automation, and transportation. They are crucial in CNC machines, robotic systems, material handling equipment, and many other setups that require accurate and controlled linear movement. The rails are usually made of materials like steel, aluminum, or other alloys, chosen for their strength, durability, and ability to maintain tight tolerances.

Types of linear rails

Linear rails are available in different types, each suited to specific applications and performance requirements. One common distinction is between profiled and round linear rails. Profiled rails, also known as linear guide rails, feature a complex cross-sectional shape with precise bearing surfaces. This design provides high rigidity and load-carrying capacity, making profiled rails ideal for applications demanding high precision, such as in CNC machining and semiconductor manufacturing. On the other hand, round rails have a cylindrical shape and are often used in applications requiring simpler linear motion, like in some types of conveyors and material handling systems. Another classification is based on the motion mechanism. Recirculating ball linear slide rails use ball bearings to reduce friction and enable smooth motion. This design is common in precision machinery. In contrast, plain linear rails rely on sliding contact between the rail and bearing, suitable for applications where moderate precision is acceptable.

Applications of linear rails

Linear rails play a critical role in various industries where precise and controlled linear motion is essential. In the manufacturing sector, they are integral components of automated machinery, CNC systems, and industrial robots. CNC machines rely on linear rails to move cutting tools with high accuracy, ensuring precise and repeatable machining processes. Industrial robots use linear rails to navigate, pick, and place objects in manufacturing environments. In the packaging industry, linear rails contribute to the efficient operation of conveyor systems, ensuring smooth and accurate product transport. Within the transportation sector, linear rails are used in various applications, such as in railway systems, where they guide the motion of train doors and provide smooth operation of sliding mechanisms. In the aerospace industry, linear rails are vital for the precise movement of components in aircraft manufacturing and control systems. Furthermore, linear rails find application in the medical field, where they are used in diagnostic equipment, robotic surgery systems, and imaging devices, contributing to the advancement of healthcare technologies.

Benefits of using linear rails

The use of linear rails offers several advantages in machinery and equipment. One of the primary benefits is the high level of precision they provide. These rails ensure accurate linear motion, which is crucial in various industries, especially in manufacturing processes that demand tight tolerances. Additionally, the smooth and controlled movement achieved by using linear bearing rails enhances the overall performance of machinery. Reduced friction and wear contribute to the longevity of the system, leading to lower maintenance requirements and longer operational life. Another advantage is the capability of linear rails to support heavy loads while maintaining stability and accuracy. This strength is particularly beneficial in applications involving the transportation of materials and components. Moreover, the modular design of linear rails allows for easy integration and customization, making them versatile components that can be adapted to different requirements. Finally, the efficiency and speed of linear motion enabled by these rails contribute to enhanced productivity in industrial settings, making them indispensable in the realm of automation and manufacturing.