Máy Cắt Laser Sợi Nóng Bán Chạy Với Giảm Giá Cao Cho Thép Không Gỉ Carbon 1500W

7.800,00 US$ - 8.400,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Cooling Mode: Air Cooling

CNSupplier

1000W 2000W 3000W kim loại laser cắt CNC sợi máy cắt laser cho thép không gỉ

12.000,00 US$ - 12.800,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Cooling Mode: Water Cooling

CNSupplier

Senfeng thế hệ mới giá tốt 1500*3000 sợi Laser kim loại máy cắt 1500W để bán

15.000,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Cooling Mode: Water Cooling

CNSupplier

Nhà máy trực tiếp sợi Laser Cutter 1000W 2000W 3000W CNC máy cắt laser trên bán

10.899,00 US$ - 11.000,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Control System Brand: Cypcut

Cooling Mode: Water Cooling

CNSupplier

Máy Cắt Laser Acctek Sợi 1000W 1500W 2000W AKJ1530F

5.580,00 US$ - 5.730,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Cooling Mode: Water Cooling

CNSupplier

kích thước lớn máy cắt lasermáy cắt laser bãomáy cắt laser công suất cao 140wmáy cắt laser arcylic9060 laser cắt giá máymáy cắt laser 4kw 6kwtiles laser cutting machinemáy cắt nông trạigiá máy cắt laser tại ấn độmáy cắt laser ấn độmáy cắt laser tại ấn độmáy cắt laser giá pakistangiá máy cắt laser ở malaysiagiá máy cắt laser ở pakistanmáy cắt laser giá malaysia

Trung quốc Gweike giá thấp CNC LF1325 sợi kim loại máy cắt laser

2.000,00 US$ - 4.299,00 US$

Min Order: 1 Bộ

Laser Type: Co2

Control System Brand: Cypcut

Cooling Mode: Water Cooling

CNSupplier

4030 CO2 cắt khắc 40W ROTARY trường hợp A3 A4 Kích thước cắt laser giá máy trong Philippines A3 laser Cutter

Sẵn sàng vận chuyển

500,00 US$ - 600,00 US$

Min Order: 1 Bộ

Shipping per piece: 370,50 US$

Laser Type: Co2

Cooling Mode: Water Cooling

Graphic Format Supported: Dxf

CNSupplier

Máy Cắt Laser Thủ Công Acrylic Giá Thấp 4060 6040

Sẵn sàng vận chuyển

420,00 US$ - 960,00 US$

Min Order: 1 Bộ

Laser Type: Co2

Control System Brand: Beckhoff

Cooling Mode: Water Cooling

CNSupplier

6 yrs

LX3015F 1kw 2000Watt 3000 Wát Sợi Máy Cắt Laser Ấn Độ Giá Kim Loại Tấm Máy Cắt Để Bán

10.000,00 US$ - 15.000,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Cooling Mode: Water Cooling

CNSupplier

Máy Cắt Laser VOIERN WR4040mini WR3020 40W Khu Vực Làm Việc 300X200 Mm Giá Máy Khắc Laser Co2

380,00 US$ - 480,00 US$

Min Order: 1 Bộ

Laser Type: Co2

Cooling Mode: Water Cooling

Graphic Format Supported: Ai

CNSupplier

Bảng Khuôn Máy Cắt Laser/Gỗ Máy Cắt Laser Giá

5.000,00 US$

Min Order: 1 Bộ

Laser Type: Co2

Control System Brand: Leetro

Cooling Mode: Water Cooling

CNSupplier

14 yrs

SenFeng Laser SF3015G 3000 Wát Laser Máy Cắt Kim Loại Giá Trực Tiếp Công Nghiệp Thiết Bị Cắt Laser Sản Xuất

29.666,00 US$ - 47.799,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Cooling Mode: Water Cooling

CNSupplier

Giá bán buôn kim loại chữ tấm ống Ống sợi CNC 500W 1000W Mini Laser Máy cắt kim loại

8.000,00 US$ - 10.000,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Control System Brand: Cypcut

Cooling Mode: Water Cooling

CNSupplier

Công Suất Cao Tế Nam Nhà Máy Giá Tấm Kim Loại Sợi Máy Cắt Laser Để Bán

8.900,00 US$ - 15.000,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Control System Brand: Cypcut

Cooling Mode: Water Cooling

CNSupplier

Máy Cắt Laser 1060 1080 Giá Rẻ Ruman

1.198,80 US$

Min Order: 1 Cái

Laser Type: Co2

Control System Brand: Ruida

Cooling Mode: Water Cooling

CNSupplier

5 yrs

Nhà Máy Giá Axial Flow 400 Wát 600 Wát CO2 Bảng Khuôn Máy Cắt Laser

20.000,00 US$ - 30.000,00 US$

Min Order: 1 Bộ

Laser Type: Co2

Cooling Mode: Water Cooling

CNSupplier

14 yrs

Máy Cắt Laser Sợi Leapion 1530H 1500 Watt Cho Máy Cắt Laser Sợi Kim Loại Giá 1000 Watt

8.000,00 US$ - 15.000,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Control System Brand: Cypcut

Cooling Mode: Water Cooling

CNSupplier

CCD Camera Tự Động Định Vị Nhãn Hiệu Máy Cắt Laser Với Giá Rẻ MC 1390

4.000,00 US$ - 6.000,00 US$

Min Order: 1 Bộ

Laser Type: Co2

Control System Brand: Ruida

Cooling Mode: Water Cooling

CNSupplier

10 yrs

Jinan Gweike Nhỏ 1390 1000 Wát 1500 Wát 2000 Wát Sợi Kim Loại Máy Cắt Laser Giá CE

19.999,00 US$ - 29.999,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Control System Brand: Cypcut

Cooling Mode: Water Cooling

CNSupplier

Bodor kinh tế một loạt thiết kế mới bodor Máy cắt laser với giá thấp nhất

34.100,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Cooling Mode: Water Cooling

CNSupplier

Tấm Thép Không Gỉ 1390 Cnc Tấm Kim Loại Máy Cắt Laser Với Giá Tốt Đẹp

18.500,00 US$

Min Order: 1 Cái

Laser Type: Fiber Laser

Cooling Mode: Water Cooling

CNSupplier

Đôi Thủ Trưởng Chi Phí Thấp Vải Máy Cắt Laser Giá Cho Vải Thăng Hoa

10.515,00 US$

Min Order: 1 Bộ

Laser Type: Co2

Control System Brand: Fanuc

Cooling Mode: Air Cooling

CNSupplier

13 yrs

Giá Đại Lý CO2 Máy Cắt Laser Bằng Thép Không Gỉ Máy Cắt Laser Kim Loại

4.500,00 US$ - 7.500,00 US$

Min Order: 1 Bộ

Laser Type: Co2

Control System Brand: Ruida

Cooling Mode: Air Cooling

CNSupplier

6 yrs

CE certificated China Bodor 3kw cnc laser cutter fiber laser metal cutting machine cheap price

32.000,00 US$ - 78.000,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Control System Brand: Beckhoff

Cooling Mode: Water Cooling

CNSupplier

9 yrs

Được Xây Dựng Trong Hệ Thống Giám Sát 5 Mm Sợi Kim Loại Giá Máy Cắt Laser

38.000,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Control System Brand: Cypcut

Cooling Mode: Water Cooling

CNSupplier

Trung Quốc Giá Rẻ 3D 5-trục CNC Máy Cắt Laser Giá SF3015

8.000,00 US$ - 15.000,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Cooling Mode: Water Cooling

CNSupplier

Hongniu Laser Sợi Máy Cắt Laser Máy Giá

44.000,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Control System Brand: Cypcut

Cooling Mode: Water Cooling

CNSupplier

Máy cắt laser CNC giá Ấn Độ 4 trục cho chết

Sẵn sàng vận chuyển

10.000,00 US$ - 15.000,00 US$

Min Order: 1 Đơn vị

Shipping per piece: 1.000,00 US$

Laser Type: Fiber Laser

Cooling Mode: Water Cooling

CNSupplier

Trung Quốc 1500W 2000W 3000W CNC 3D Laser Máy Cắt Ống Ấn Độ Đại Lý Giá Thép Sắt Sợi Máy Cắt Laser Cho Ống Ống

38.000,00 US$ - 52.000,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Cooling Mode: Water Cooling

CNSupplier

2 yrs

Cheap Price Made In China Accurl Laser Cutting Machine

2.200,00 US$ - 2.450,00 US$

Min Order: 1 Bộ

Laser Type: Co2

Cooling Mode: Water Cooling

CNSupplier

WILA LASER 500w 1000w 1500w fiber metal laser cutting machine promotional price for sale

23.800,00 US$ - 24.900,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Control System Brand: Beckhoff

Cooling Mode: Water Cooling

CNSupplier

8 yrs

HUAXIA Chất Lượng Cao Top Bán Laser Diện Tích Nhỏ 3015 Máy Cắt Laser Sợi Cnc Giá Máy Cắt Laser Kim Loại 1000W-4000W

12.000,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Cooling Mode: Air Cooling

CNSupplier

CA-1530 2060 Tấm Kim Loại/Ống Máy Cắt Laser Trung Quốc Tế Nam Máy Cắt Laser 1000W 2000W Giá

15.000,00 US$ - 35.000,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Control System Brand: Cypcut

Cooling Mode: Water Cooling

CNSupplier

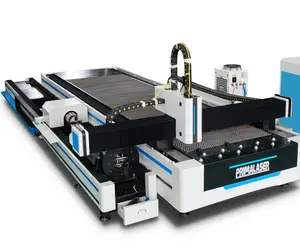

Prima Faber Laser Máy Cắt 1000W Nhà Máy Giá

25.000,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Control System Brand: Cypcut

Cooling Mode: Air Cooling

CNSupplier

9 yrs

Tốc Độ Cao Co2 CNC PVC Cắt Laser Giá Máy Tại Ấn Độ Cho Khắc Gỗ

3.376,62 US$

Min Order: 1 Bộ

Laser Type: Co2

Cooling Mode: Water Cooling

Graphic Format Supported: Dxf

CNSupplier

Cho ăn tự động cắt laser tia laser máy cắt giá máy tại ấn độ euro máy cắt laser với CE giấy chứng nhận

6.000,00 US$

Min Order: 1 Bộ

Laser Type: Co2

Cooling Mode: Water Cooling

CNSupplier

8 yrs

Máy Cắt Laser 5 Trục Giá 3kw 3015 Sợi

Sẵn sàng vận chuyển

25.000,00 US$

Min Order: 1 Bộ

Shipping per piece: 3.500,00 US$

Laser Type: Fiber Laser

Control System Brand: Cypcut

Cooling Mode: Water Cooling

CNSupplier

Thượng Hải Cypcut Nhật Bản Servo sợi laser cắt kim loại bằng laser giá máy tại Ấn Độ

12.499,00 US$ - 14.499,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Control System Brand: Cypcut

Cooling Mode: Water Cooling

CNSupplier

6 yrs

Nhà Máy Cung Cấp Giảm Giá Laser Gravierer 32-Bit Bo Mạch Chủ 450nm Máy Cắt Laser Với Bảo Vệ An Toàn Laser CNC

Sẵn sàng vận chuyển

332,00 US$ - 359,00 US$

Min Order: 1 Cái

Shipping per piece: 27,00 US$

Laser Type: Diode

Cooling Mode: Air Cooling

Graphic Format Supported: Bmp

CNSupplier

3015 1000 W 2kw 4Kw CNC Sợi Máy Cắt Laser Kim Loại Ống Cho Cả Hai Thép Không Gỉ Tấm Sợi Cắt Laser giá Máy

39.800,00 US$

Min Order: 1 Bộ

Laser Type: Fiber Laser

Cooling Mode: Water Cooling

CNSupplier

9 yrs

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4