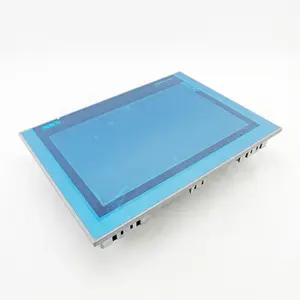

1 개의 안락 패널 TP1200 안락 Hmi tp1200 에서 제일 질 본래 Hmi 터치스크린 6AV2124-0MC01-0AX0 Plc hmi 전부

₩334,692 - ₩369,556

Min Order: 1 개

CNSupplier

DELTA HMI DOP-107BV DOP-107CV DOP-107DV DOP-107WV DOP-107EV DOP-107EG DOP100 브랜드-새롭고 독창적 인 7 인치 HMI 터치 스크린

₩104,592 - ₩223,128

Min Order: 5 개

CNSupplier

7 yrs

6AV2124-0MC01-0AX0 심플 HMI TP1200 컴포트 6AV21240MC010AX0

₩1,436,385 - ₩1,716,689

Min Order: 1 개

CNSupplier

6AV2124-0MC01-0AX0 HMI TP1200 컴포트 패널 6av2124-0mc01-0ax0 hmi 12 인치 Simatic TP1200 지멘스

₩1,143,530 - ₩1,185,366

Min Order: 1 에이커

CNSupplier

1 yrs

Simatic 318 CPU PLC HMI S7 300 S7-318 CPU318-2DP 모듈 6ES7318-2AJ00-0AB0

₩627,547 - ₩767,002

Min Order: 1 유닛

CNSupplier

Simatic 318 CPU PLC HMI S7 300 S7-318 CPU318-2DP 모듈 6ES7318-2AJ00-0AB0

₩418,365 - ₩697,275

Min Order: 2 유닛

CNSupplier

2 yrs

지멘스 Simatic 318 CPU PLC HMI S7 300 S7-318 CPU318-2DP 모듈 6ES7 318-2AJ00-0AB0 재고 있음

₩744,689 - ₩879,960

Min Order: 1 개

CNSupplier

핫 세일 터치 스크린 12 인치 TP1200 6AV2124-0MC01-0AX0 HMI TP1200 컴포트 패널 재고

₩2,231,277 - ₩2,816,988

Min Order: 1 개

CNSupplier

9 yrs

통합 plc 및 터치 스크린 hmi

배송 준비 완료

₩488,092 - ₩502,038

Min Order: 1 개

Shipping per piece: ₩42,590

CNSupplier

16 yrs

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4