Popular in your industry

Related Searches:

Top categories

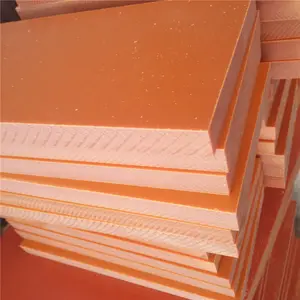

About high pressure board

High pressure boards are manufactured using multiple sheets of wood fibers and resin pressed together under high temperature and pressure. These boards are engineered for exceptional strength, durability, and versatility, making them ideal for various applications in both residential and commercial settings. The high pressure applied during the manufacturing process significantly enhances the board's structural integrity, allowing it to withstand heavy loads and resist warping or bending. The composition of high pressure boards can vary, with some incorporating additional layers of decorative or protective materials to meet specific performance requirements.

Types of high pressure boards

One common type of high pressure board is the high-pressure laminate (HPL) board. HPL boards are crafted by pressing multiple layers of kraft paper impregnated with resin and a decorative layer, often mimicking the look of wood, stone, or other materials, under high pressure. This process creates a robust and visually appealing surface that is highly resistant to scratches, impact, and moisture. HPL boards are commonly used for countertops, cabinetry, wall claddings, and furniture due to their durability and aesthetic versatility. HPL boards are also known for their ease of maintenance, making them a popular choice in environments that require a combination of durability and aesthetics.

Applications of high pressure boards

High-pressure boards can be utilized in various applications across industries. In the construction sector, these boards are frequently used for wall paneling, partitions, flooring, and exterior cladding. Their durability, resistance to moisture, and ease of maintenance make them a preferred choice for high-traffic areas. In the furniture industry, high-pressure boards are commonly employed for manufacturing sturdy and stylish furniture pieces, including tables, cabinets, and shelving units. These boards are also a popular choice for creating modular furniture due to their ability to withstand weight and frequent assembly and disassembly. In the transportation industry, high-pressure boards find application in the manufacturing of vehicle interiors, including cabinetry, wall panels, and flooring, in buses, trains, and recreational vehicles. Their robustness and ability to withstand wear and tear make them suitable for demanding environments. Additionally, high-pressure boards are used in the production of doors, especially those requiring high durability and resistance to external elements. These boards are also incorporated in industrial settings for workbenches, tabletops, and machinery surfaces, where strength and longevity are paramount.

The advantages of high pressure boards

High pressure boards offer a host of advantages due to their robust construction and versatile characteristics. One of the primary benefits of high pressure boards is their exceptional strength and durability, making them capable of withstanding heavy loads and resisting damage from impacts and abrasions. This durability contributes to the long lifespan of these boards, reducing the need for frequent replacements and maintenance. High pressure boards are also known for their resistance to moisture, making them suitable for applications in environments prone to humidity or occasional wetness. Additionally, the high-pressure manufacturing process results in boards with consistent thickness and flatness, ensuring uniformity and ease of installation. The surface of these boards can be customized with various finishes, such as matte, gloss, or textured, to meet specific design preferences. This versatility extends to the aesthetic realm, as high pressure boards are available in a wide range of colors and patterns, including wood grains, stone textures, and solid hues. These design options allow for the creation of visually appealing spaces while benefiting from the board's practical advantages. Furthermore, high pressure boards are eco-friendly, as they are often made from sustainable materials and can be recycled, contributing to a greener approach in construction and design.