Экструдированный Acetal C pomalux жесткий ESD POM стержень acetal сополимер стержни pomalux

6,00 $ - 10,00 $

Min Order: 5 кА

CNSupplier

6 yrs

Заводская цена, легированная сталь, круглый стержень 40Cr 4140 4130 42Crmo Cr12mov H13 D2, стержень из инструментальной стали, цена за тонну

490,00 $ - 750,00 $

Min Order: 1 т

CNSupplier

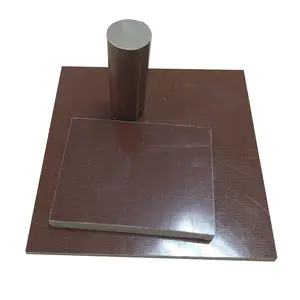

Изоляционный стержень из бакелитовой смолы, ткань из фенольного хлопка, ламинат, стержень 3725 PFCC41, стержень лучшего качества

1,50 $ - 4,20 $

Min Order: 1 кг

CNSupplier

7 yrs

ASTM 1035 1045 1050 S45c Q195 Q215 Q235 Q275 Q345 H13 металлические стержни круглые 10 мм 12 мм режущая сталь углеродистая сталь стержень

0,99 $ - 5,00 $

Min Order: 10 кг

CNSupplier

1 yrs

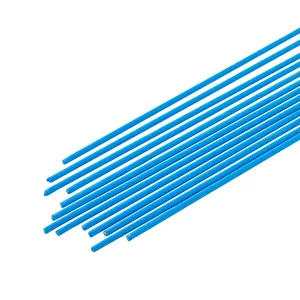

Горячая Распродажа, коррозионная устойчивость, белый 100% девственный фторопласт из ПТФЭ

1,80 $ - 2,00 $

Min Order: 10 шт.

CNSupplier

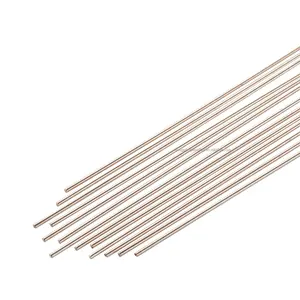

Оптовая цена, качественный 15% Серебряный медный фосфорный паяльный стержень | BCuP-5 | Чашка 284 | BCu80AgP для медных сплавов

135,27 $ - 150,27 $

Min Order: 20 кг

CNSupplier

2 yrs

Микропроцессорный 34% Серебряный паяльный стержень серебристый медный фосфорный оловянный сварочный стержень из алюминиевого сплава

298,39 $ - 309,39 $

Min Order: 20 кг

CNSupplier

2 yrs

Качественный 15% Серебряный медный фосфор паяльный стержень | BCuP-5 | CuP 284 | BCu80AgP для медных сплавов

133,45 $ - 148,45 $

Min Order: 20 кг

CNSupplier

2 yrs

BAg-8 | Ag272 | BAg72Cu | 72% серебряная проволока для пайки, Ag Cu Серебряный паяльный стержень для пайки медных сплавов

650,94 $ - 670,94 $

Min Order: 20 кг

CNSupplier

2 yrs

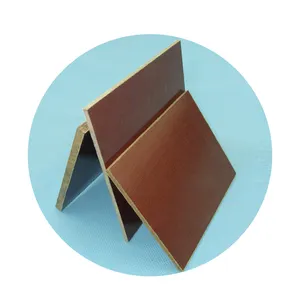

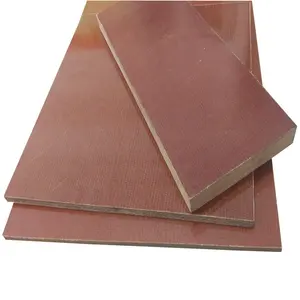

Fenolico-celotex-HGW 2082 фенольная хлопковая ткань ламинат в доске или стержне

1,00 $ - 2,20 $

Min Order: 100 кг

CNSupplier

Точный шариковый винт с ЧПУ SFU2510, шариковый винт и шариковая гайка

Готово к отправке

2,00 $ - 78,00 $

Min Order: 1 м

CNSupplier

10 yrs

Изоляционный материал, темно-коричневая фенольная хлопчатобумажная ткань, ламинированный лист/стержень на основе фенольной бумаги 3025

1,00 $ - 2,20 $

Min Order: 100 кг

CNSupplier

6 yrs

Стержень HGW 2088, тканый бакелит hgw 2088, слои хлопчатобумажной ткани, скрепленные фенольной смолой

1,00 $ - 2,20 $

Min Order: 100 кг

CNSupplier

BAg-36 | Ag145 | BAg45CuZnSn | Пруток из серебра 45% пробы с флюсовым покрытием Ag Cu Zn Sn сплав олова и меди

403,88 $ - 423,88 $

Min Order: 5 кг

CNSupplier

2 yrs

Электрический изоляционный фенольный хлопок Тип Hgw 2082 фенольная хлопчатобумажная ткань ламинированный 3025 бакелитовый стержень/лист

1,00 $ - 2,20 $

Min Order: 100 кг

CNSupplier

6 yrs

Трансформатор используется электроизоляционный материал hgw 2082 PFCC 201 фенольная хлопчатобумажная ткань лист и стержень

1,90 $ - 3,90 $

Min Order: 100 кг

CNSupplier

Паяльный стержень с покрытием из серебра 40% пробы Ag Cu Zn Серебряный медный сплав для пайки цинка

366,77 $ - 386,77 $

Min Order: 5 кг

CNSupplier

2 yrs

Высококачественная фенольная смола, ламинированный бакелитовый фенольный хлопок типа Hgw 2082 3025, лист из текстилата

1,00 $ - 2,20 $

Min Order: 100 кг

CNSupplier

6 yrs

BCuP-5 | Чашка 284 | BCu80AgP | 15% серебряной пайки стержень Ag Cu P, серебро, медь, фосфор твёрдый припой

135,27 $ - 150,27 $

Min Order: 20 кг

CNSupplier

2 yrs

BCuP-3 | Чашка 281 | BCu89PAg | 5% серебряной пайки стержень Ag Cu P, серебро, медь, фосфор твёрдый припой

53,64 $ - 58,64 $

Min Order: 20 кг

CNSupplier

2 yrs

Хлопковая доска из фенолового волокна стандартного размера 3025, 10 пряжи, 7 пряжи, 21 пряжа

1,00 $ - 2,20 $

Min Order: 100 кг

CNSupplier

BCuP-6 | Чашка 280 | BCu91PAg | 2% серебряной пайки стержень Ag Cu P, серебро, медь, фосфор твёрдый припой

27,80 $ - 32,30 $

Min Order: 20 кг

CNSupplier

2 yrs

Фенольный бакелитовый ламинированный хлопковый лист PF CC 201 /Hgw 2082 и стержень PFCC 42

1,00 $ - 2,20 $

Min Order: 100 кг

CNSupplier

BAg-5 | Ag245 | BAg45CuZn | 45% серебряный паяльный стержень Ag Cu Zn Серебряный медный сплав цинка

393,88 $ - 403,88 $

Min Order: 20 кг

CNSupplier

2 yrs

Ag130 | BAg30CuZnSn | 30% Серебряный паяльный стержень Серебряный Ag Cu Zn Sn Серебряный медный цинковый сплав для пайки

265,66 $ - 274,66 $

Min Order: 20 кг

CNSupplier

2 yrs

BAg35CuZnSn | 35% Серебряный паяльный стержень Серебряный Ag Cu Zn Sn Серебряный медный цинковый сплав для пайки олова

312,07 $ - 322,07 $

Min Order: 20 кг

CNSupplier

2 yrs

BCuP-9 | Чашка 385 | BCu87PSn(Si) | cupsn Cu P Sn меди фосфора оловянный пруток твёрдый припой

34,46 $ - 41,46 $

Min Order: 20 кг

CNSupplier

2 yrs

20% Серебряный паяльный стержень Ag Cu Zn Sn Серебряный медный сплав олова

181,85 $ - 190,85 $

Min Order: 20 кг

CNSupplier

2 yrs

Cu-P-Sn поток покрытием пруток медь фосфора олова твёрдый припой | BCuP-9 | Чашка 385 | BCu87PSn(Si)

34,46 $ - 41,46 $

Min Order: 20 кг

CNSupplier

2 yrs

Новейший BCuP-6 | Чашка 280 | BCu91PAg | 2% Серебряный паяльный стержень Ag Cu P серебристый медный фосфорный паяльный сплав

28,40 $ - 32,90 $

Min Order: 20 кг

CNSupplier

2 yrs

Профессиональный 5% Серебряный паяльный стержень, Серебряный медный фосфорный паяльный сплав | BCuP-3 | Чашка 281 | BCu89PAg

52,54 $ - 57,54 $

Min Order: 20 кг

CNSupplier

2 yrs

Cu-P-Sn пруток медь фосфора олова твёрдый припой | BCuP-9 | Чашка 385 | BCu87PSn(Si)

13,19 $ - 16,49 $

Min Order: 20 кг

CNSupplier

2 yrs

15% серебро пруток, серебро, медь, фосфор твёрдый припой | BCuP-5 | Чашка 284 | BCu80AgP

135,27 $ - 150,27 $

Min Order: 20 кг

CNSupplier

2 yrs

OEM ODM чашка 180 | BCu93P | 0% Серебряный паяльный стержень для сварки окружающей среды Cu P медный фосфорный паяльный сплав

11,97 $ - 14,87 $

Min Order: 20 кг

CNSupplier

2 yrs

Прямая поставка BCuP-6 | Чашка 280 | BCu91PAg | 2% Серебряный паяльный стержень Ag Cu P серебристый медный фосфорный паяльный сплав

28,40 $ - 32,90 $

Min Order: 20 кг

CNSupplier

2 yrs

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4