Understanding the GEA Milking Machine

The GEA milking machine stands as a cornerstone in modern dairy farming, streamlining the milking process with precision and efficiency. This machinery is designed to cater to the needs of dairy operations of various scales, ensuring a consistent and gentle milking experience.

Key Features of GEA Milking Equipment

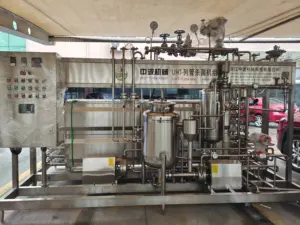

At the heart of the GEA milking equipment are its integral components, including the pulsator, claws, teat cups, and milk tubes. The pulsator plays a crucial role in regulating the machine's operation, preventing the accumulation of lymph and blood near the teats, thus ensuring animal welfare. The claw acts as a hub, connecting the teat cups to the pulsator and milk tubes, and is crafted from durable materials like plastic or stainless steel for longevity. Teat cups serve as the contact point with the animals, designed for comfort and protection, while the milk tubes facilitate the seamless flow of milk and air, essential for maintaining teat health.

Considerations for Selecting a Milking Machine

When considering the acquisition of a GEA milk machine, several factors should be evaluated. Hygiene is paramount, as it directly impacts milk quality and animal health; thus, machines that are easy to clean post-milking are essential. Durability is another critical aspect, with machines needing to withstand the rigors of daily use. Additionally, the availability of spare parts ensures that any potential downtime can be minimized. Lastly, the operational noise level is a factor for both human and animal comfort, with quieter machines being preferable.

Applications and Advantages of GEA Milking Systems

The GEA milking systems are versatile, suitable for various dairy farm sizes and types. They offer the advantage of consistent milking routines, contributing to stable milk production. The integration of GEA milk meters within these systems allows for precise monitoring of milk yield, aiding in herd management and health monitoring. The design of these machines also emphasizes animal comfort, which can lead to better milk let-down and quality.

Materials and Construction

The construction of GEA milk machines involves materials selected for their durability and ease of maintenance. Stainless steel components ensure resistance to corrosion and ease of cleaning, while high-grade plastics offer lightweight strength. This combination of materials contributes to the overall longevity and reliability of the milking systems.

Choosing the Right GEA Milking Machine

Selecting the appropriate GEA milking machine involves assessing the specific needs of your dairy operation. Consider the size of your herd, the frequency of milking, and the infrastructure of your milking parlor. It is advisable to review the various models available to identify the one that aligns with your operational requirements, ensuring an efficient and effective milking process.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4