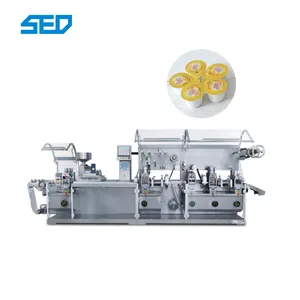

Alibaba.com cung cấp một số loại máy đóng gói vỉ thực phẩm. để bán bởi các nhà cung cấp được chứng nhận, đảm bảo các sản phẩm hiện đại, chính xác cao với kết quả vượt trội. Chúng được thiết kế để sử dụng lâu dài, đảm bảo độ bền và hiệu suất tối ưu. Các sản phẩm thường được tìm kiếm là máy đóng gói vỉ thực phẩm. thiết bị hàn và máy chiết rót. Từ nhà máy chưng cất nước khoáng đến máy móc công nghiệp, chúng có sẵn cho các ứng dụng khác nhau ở các công suất sản xuất khác nhau.

máy đóng gói vỉ thực phẩm. được sản xuất tuân theo các tiêu chuẩn công nghiệp bằng cách sử dụng nguyên liệu chất lượng cao với công nghệ tiên tiến mới nhất. Nhiều lựa chọn sản phẩm điện tử có sẵn cho người mua hàng. Các thiết kế tùy chỉnh được xây dựng cho sự xuất sắc đi kèm với một bảo hành. Chúng được các chuyên gia trong lĩnh vực này kiểm tra về độ an toàn, đảm bảo rằng tất cả các thông số đều được đáp ứng đầy đủ.

Hầu hết máy đóng gói vỉ thực phẩm. được thiết kế cho các cài đặt chuyên nghiệp do hệ thống dung lượng cao của chúng. Từ thiết bị máy chiết rót chai nước uống Aqua tùy chỉnh đến Máy in PCB Stencil hiệu quả cao và giá rẻ đến Máy phân phối keo lỏng, Alibaba.com cung cấp nhiều lựa chọn máy móc công nghiệp. Danh mục tổng hợp với thông tin chi tiết về từng sản phẩm luôn có sẵn cho người mua hàng.

Từ nhà hàng đến nhà máy, Alibaba.com cung cấp máy móc hiện đại với công suất lớn cho các ứng dụng khác nhau. Chúng được xây dựng để có hiệu suất tối ưu và hoạt động trơn tru. Các máy đóng gói vỉ thực phẩm. tiết kiệm và với các nhà cung cấp trên toàn cầu, mọi nhu cầu của người mua hàng có thể được đáp ứng dễ dàng. Hầu hết các sản phẩm đều có sẵn với mức giá hàng đầu trong ngành và có bảo hành.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4