About products and suppliers

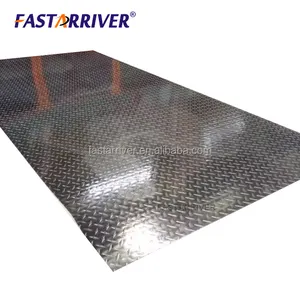

Khám phá phạm vi độc quyền của. embossed copper sheet tại Alibaba.com cho các mục đích sử dụng thương mại và công nghiệp khác nhau. Bạn có thể mua. embossed copper sheet có độ dày thay đổi ở dạng hợp kim hoặc nguyên chất .. embossed copper sheet thích hợp cho một số ngành, cụ thể là HVAC, hàng không vũ trụ, Thiết bị điện, v.v. Độ tinh khiết của hàng hóa từ 99,5 đến 99,9%.

embossed copper sheet tại Alibaba.com có thể được tùy chỉnh theo kích thước mong muốn. Độ cứng thay đổi theo thang từ 1/16 H đến độ cứng toàn phần. Sự kéo dài của. embossed copper sheet nếu tiếp xúc với nhiệt, cũng được đề cập để thể hiện tính linh hoạt của vật liệu. Có một loạt các phương pháp xử lý bề mặt được áp dụng như chân tóc, bàn chải, máy nghiền, thổi cát, v.v. Các tấm được chuẩn bị bằng cách sử dụng một trong các phương pháp như cán nóng, cán nguội, rèn, đúc, ủ, v.v. Điểm mạnh cuối cùng của các mặt hàng này nằm trong khoảng từ 150 đến 400. Dạng hợp kim là đồng thau hoặc đồng. Tất cả các gợi ý cần thiết liên quan đến. embossed copper sheet có sẵn trên trang web.

embossed copper sheet có khả năng dẫn nhiệt và dẫn điện tuyệt vời. Chúng cũng là một lựa chọn thuận tiện cho hệ thống làm mát ô tô .. embossed copper sheet được sử dụng trong ngành hàng không vũ trụ, như trong ống lót và vòng bi. Vỏ và trục tàu biển được chế tạo bằng cách sử dụng các sản phẩm này, nhờ khả năng chống gỉ và sinh sản của vi sinh vật tự nhiên. Ngoài ra,. embossed copper sheet có thể được sử dụng để tạo đồ dùng, tấm phản chiếu năng lượng mặt trời, vải bọc, thiết bị gia dụng và điện tử tiêu dùng.

Hấp dẫn. embossed copper sheet cung cấp tại Alibaba.com để nhận được những ưu đãi này theo tầm kinh tế của bạn. Mua sắm từ uy tín. nhà cung cấp embossed copper sheet để nhận được ưu đãi tốt nhất với giá tốt nhất. Có được lợi thế hơn đối thủ cạnh tranh của bạn. Gửi báo giá của bạn ngay bây giờ, và bạn sẽ rất vui vì đã đưa ra quyết định này.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4