EDM Chuck điện Spark xả lịch thi đấu điện cực chỉnh Chuck

Sẵn sàng vận chuyển

145,00 US$ - 155,00 US$

Min Order: 1 Cái

Shipping per piece: 33,45 US$

CNSupplier

1 yrs

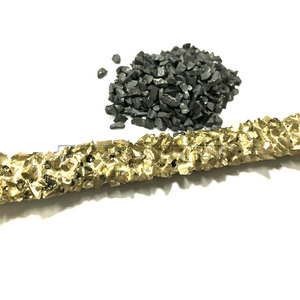

Hot bán EDM dây đồng điện cực cứng 0.25mm dây đồng

9,20 US$ - 10,00 US$

Min Order: 50 Kilogram

CNSupplier

1 yrs

Điện cực khai thác vonfram Đồng M1.2-M36 được sử dụng trong EDM

20,00 US$ - 68,00 US$

Min Order: 1 Kilogram

CNSupplier

1 yrs

điện cực phẫu thuật tái sử dụngđiện cực vòng hàng chụcđiện cực phẫu thuật dùng một lầnđiện cực kim emgdụng cụ phẫu thuật điện cựcđiện cực bút chì kim điện cực1mm edm điện cựcđiện cực khớpđiện cực dựa trên cobanđiện cực edmđiện cực rutiledm khai thác điện cựcđiện cực kịp thờiedm điện cực nhà sản xuấtđiện cực tantali

Điện Cực Đồng Vonfram Cho Máy Edm Điện Cực W75Cu25 WCu

70,00 US$

Min Order: 1 Kilogram

CNSupplier

11 yrs

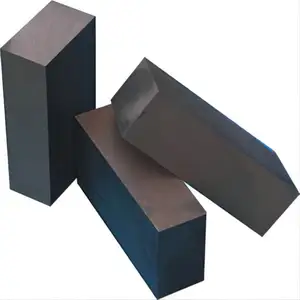

Graphite Điện Cực Cho Wirecut EDM Máy Giá Dụng Cụ

3.500,00 US$ - 28.500,00 US$

Min Order: 1 Bộ

CNSupplier

16 yrs

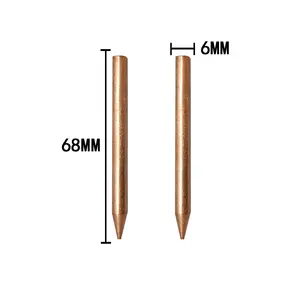

Xe cơ thể sửa chữa tấm kim loại hàng tiêu dùng Đồng điện cực cho tia lửa EDM điện cực xả

0,06 US$ - 0,08 US$

Min Order: 50 Cái

CNSupplier

3 yrs

Ống Điện Cực Đồng Dia 1.0Mm/Dia0.2mm-3.0Mm/Khoan Edm

0,10 US$ - 10,00 US$

Min Order: 10 Cái

CNSupplier

10 yrs

DD703.30 Điện Cực 3Mm Đường Kính Khoan Tối Đa Máy Khoan Edm Dd703

4.400,00 US$

Min Order: 1 Bộ

CNSupplier

Điện xả phát ra tia lửa máy công cụ cnc edm chết chìm máy

6.500,00 US$ - 7.800,00 US$

Min Order: 1 Bộ

CNSupplier

CNC EDM a45h ra <0.1um độ chính xác cao c-loại gương tự động châm ngòi EDM máy CNC Die Sinker EDM máy

25.999,00 US$

Min Order: 1 Bộ

CNSupplier

CNC EDM chết chìm máy với C trục và điện cực tự động Changer

35.000,00 US$ - 36.500,00 US$

Min Order: 1 Cái

CNSupplier

12 yrs

Đa lỗ EDM Đồng điện cực 0.8mm kênh EDM ống đồng 0.8mm

0,66 US$ - 0,69 US$

Min Order: 200 Kilogram

CNSupplier

9 yrs

Wirecut máy sản phẩm 2020 Cung cấp chết máy cắt CNC dây cắt EDM mới Pakistan dk77 32 35 40 50 2022 2100 esuntek

15.500,00 US$ - 20.050,00 US$

Min Order: 1 Bộ

CNSupplier

10 yrs

Gương CNC EDM chết chìm Máy D540 Đồng Graphite điện cực giá thấp bán sỉ độ nhám cao EDM Sinker máy

8.800,00 US$ - 11.000,00 US$

Min Order: 1 Bộ

CNSupplier

6 yrs

Chất lượng cao mới nhất tungsten carbide điện cực 0.3mm EDM Carbide que hàn 1.6mm 3.2mm

42,80 US$ - 46,80 US$

Min Order: 1 Kilogram

CNSupplier

12 yrs

Đồng nguyên chất Metric EDM chủ đề điện cực 35mm chiều dài 55mm Tổng chiều dài que hàn

Sẵn sàng vận chuyển

2,20 US$ - 16,50 US$

Min Order: 2 Cái

Shipping per piece: 9,56 US$

CNSupplier

1 yrs

1000W Mini Portable Broken Tap Removal Sparking Máy Cắt Thiết Bị EDM Với Điện Cực Đồng

741,00 US$ - 836,00 US$

Min Order: 1 Bộ

CNSupplier

9 yrs

D703.30 Điện Cực 3 Mm Đường Kính Khoan Tối Đa Edm Máy Khoan Dd703

3.300,00 US$ - 3.700,00 US$

Min Order: 1 Bộ

CNSupplier

Máy Khoan Đường Kính Tối Đa 3Mm Tia Lửa Điện Cực DZ703 Máy Khoan Thẳng Đứng Để Bàn EDM

4.282,15 US$ - 4.330,26 US$

Min Order: 1 Bộ

CNSupplier

Chất lượng cao dây EDM dk7755 dk7763 dk7780 CNC dây EDM máy công cụ

3.000,00 US$ - 3.500,00 US$

Min Order: 1 Bộ

CNSupplier

2 yrs

EDM điện cực người sáng tạo chết chìm máy điện cực

3.500,00 US$ - 28.500,00 US$

Min Order: 1 Bộ

CNSupplier

1 yrs

Máy Khoan Edm Siêu Cnc Tốc Độ Khoan D703 30-60Mm/Phút

1.949,00 US$ - 1.969,00 US$

Min Order: 1 Bộ

CNSupplier

2 yrs

ZNC350 EDM Phát Ra Tia Lửa Erision Die Chìm Máy Giá

8.000,00 US$ - 10.153,85 US$

Min Order: 1 Cái

CNSupplier

9 yrs

Máy Làm Khuôn Kim Loại Được Thiết Kế Hiện Đại Máy Cắt Dây Edm Máy Cắt Dây Điện Cực Máy Khoan Dây Edm Mini

5.200,00 US$ - 5.600,00 US$

Min Order: 1 Bộ

CNSupplier

Giá Của Máy Edm Máy Dây Edm Mini Wedm Xách Tay Máy Cắt Dây Edm Dk7745

5.690,00 US$ - 5.900,00 US$

Min Order: 1 Bộ

CNSupplier

CNC dây cắt EDM Máy sh500 sh600 sh800 CNC Máy Graphite điện cực Máy tính để bàn

3.200,00 US$ - 4.500,00 US$

Min Order: 1 Bộ

CNSupplier

Chất lượng cao phẳng dây đồng thau cáp đồng dây EDM Máy dk7745 với đảm bảo chất lượng

4.500,00 US$ - 4.700,00 US$

Min Order: 1 Bộ

CNSupplier

1 yrs

BJX-400 mediem tốc độ Trung Quốc Tốc độ cắt cao CNC dây EDM các bộ phận máy

1.000,00 US$ - 1.500,00 US$

Min Order: 1 Bộ

CNSupplier

1 yrs

EDM Điện Cực Đấng Tạo Hóa Chết Chìm Máy Điện Cực

3.500,00 US$ - 28.500,00 US$

Min Order: 1 Bộ

CNSupplier

16 yrs

NEW Bica ZNC Hoặc 450 EDM Xói Mòn Edm Máy Edm Chết Chìm Máy Xói Mòn Máy

17.800,00 US$

Min Order: 1 Bộ

CNSupplier

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4