Exploring the Versatility of Ceramic Ovens for Brick Manufacturing

The ceramic oven for brick is an essential component in the field of industrial manufacturing, playing a pivotal role in the production of high-quality bricks. These ovens, also known as kilns, are designed to withstand and manage high temperatures necessary for the firing process. This introduction delves into the various aspects of ceramic ovens, highlighting their types, applications, and features without making absolute claims or promises.

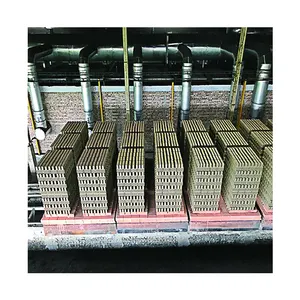

Types and Applications of Ceramic Ovens

Ceramic ovens for brick production come in various types, each tailored to specific melting and firing needs. The primary categories include open furnace and enclosed furnace designs, catering to different metal processing requirements. These ovens are not limited to a single function but are versatile in handling various metals such as iron, aluminum, and copper, as well as precious metals like gold and silver. The application of these ovens extends to multiple industries, where they are instrumental in creating a range of metal products by melting scrap metals and reforming them into new shapes and forms.

Features and Technical Specifications

The technical prowess of a ceramic melting furnace is evident in its capacity to reach temperatures ranging from 1,750 to 2,100 degrees Celsius, suitable for melting a vast array of metals. These furnaces are engineered to handle significant weights, with some capable of managing up to 20 tons. The power input for these robust machines varies, typically between 380v and 950v, while their working power can range from 180kw to a formidable 2,000kw. Advanced models are equipped with large capacitor banks to ensure current stability, which is crucial for the consistent operation of the industrial furnace.

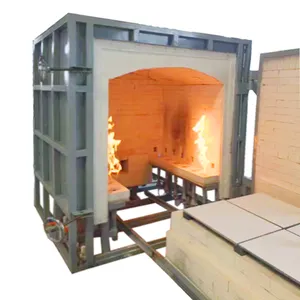

Operational Efficiency and Safety Features

Efficiency in operation is achieved through the integration of a PLC system, which simplifies the control of the ceramic oven for brick. Safety is paramount in the design of these ovens, with built-in features such as circuit breakers that automatically engage in the event of a fault. Additionally, the melting pots are designed to tilt up to 95 degrees, facilitating the easy transfer of molten metal. This feature, combined with a water-cooling system, ensures both efficiency and safety during the metal handling process.

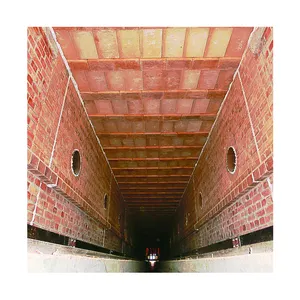

Materials and Construction Advantages

The construction of a ceramic kiln for brick is a testament to the advancement in material science. These ovens are built with high-grade insulation materials to withstand extreme temperatures and prevent heat loss. The use of hydraulic pressure systems in some models enhances the tilting mechanism, providing a forceful yet controlled movement of the furnace pot. The durability of these materials ensures the longevity of the ovens, making them a reliable component in industrial settings.

In conclusion, the ceramic oven for brick category encompasses a range of ovens designed for the high-temperature processing of metals. With various types available to suit different industrial needs, these ovens are a cornerstone in manufacturing sectors that require precise and safe metalworking capabilities. For those in search of such equipment, a comprehensive selection is available to explore, ensuring that the right machine meets specific operational demands.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4