Understanding Camshaft Bearings

Camshaft bearings play a pivotal role in engine efficiency and longevity, acting as a bridge between the camshaft and the engine block. These bearings ensure the camshaft rotates with minimal friction, a critical aspect of engine performance. This introduction delves into the nuances of camshaft bearings, their types, applications, and features, providing a comprehensive overview for industrial buyers.

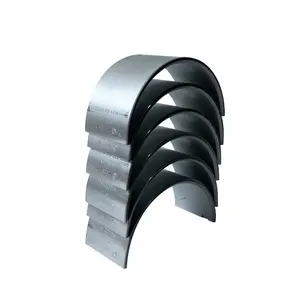

Types and Applications of Camshaft Bearings

The industrial landscape showcases a variety of camshaft bearings, each tailored to specific engine types and performance requirements. From roller cam bearings known for their durability in high-load engines to ls cam bearings designed for specific engine models, the selection is extensive. These components are integral to a wide array of machinery, including excavators, forklift trucks, and even aircraft engines, ensuring their smooth operation and reliability.

Features and Materials

When selecting camshaft bearings, understanding the material composition is crucial. Options like durabond camshaft bearings offer robustness, thanks to their high-quality material construction. The features of these bearings are diverse, with some designed for high-speed applications and others, like ch25 cam bearings, catering to specific engine designs. The precision in design and material choice directly impacts the bearing's performance and the engine's overall health.

Installation and Maintenance

The process of installing cam bearings requires precision and the right tools, such as cam bearing tools. Maintenance, including replacing cam bearings or changing cam bearings, is essential for engine upkeep. For those working on specific models, tools like ls1 cam bearings tools are designed to facilitate accurate installation and maintenance, ensuring the longevity of the engine's performance.

Advantages of Quality Camshaft Bearings

Quality camshaft bearings reduce friction and wear, leading to improved engine performance and fuel efficiency. They also contribute to quieter engine operation, which is particularly beneficial in environments where noise reduction is essential. The use of specialized bearings, such as 5.3 cam bearings, can provide tailored solutions that enhance engine dynamics for specific models.

Choosing the Right Camshaft Bearings

Selecting the correct camshaft bearings is a critical decision that affects engine integrity and performance. Buyers must consider factors such as compatibility, intended application, and environmental conditions. While the Alibaba platform connects buyers with a vast array of options, it is the buyer's responsibility to ensure the chosen bearings meet their specific engine requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4