Introduction to Boring Machine Robbi

The boring machine Robbi represents a category of precision engineering equipment designed to bore holes in various materials. These machines are pivotal in numerous industrial applications, ensuring the creation of accurate and consistent bores. Typically utilized in machining centers, the Robbi boring machine is synonymous with reliability and precision.

Types and Applications

There are several types of boring machines, each serving specific industrial needs. From horizontal boring machines for large workpieces to vertical machines for finer, detailed work, the applications are diverse. They are extensively used in automotive, aerospace, and heavy machinery industries for tasks such as engine refurbishing and cylinder boring.

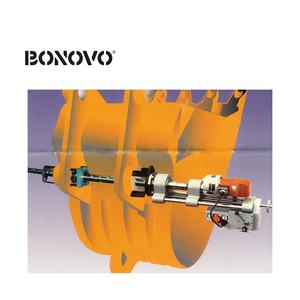

Technical Features

A cylinder boring machine like Robbi is equipped with advanced features to enhance performance. These include digital readouts for accuracy, variable spindle speeds, and automated feed mechanisms. The construction of these machines often involves robust materials that provide stability and longevity, ensuring precise operations over extended periods.

Materials and Advantages

The materials used in the construction of a Robbi boring machine are selected for their durability and performance. High-grade steel and cast iron form the main structure, providing the necessary rigidity. The advantages of using such a machine include enhanced precision in bore dimensions and surface finish, as well as improved speed and efficiency in manufacturing processes.

Operational Excellence

Operational excellence in engine boring machines is critical. Robbi machines are designed to minimize vibration and maintain accuracy even under demanding conditions. The user-friendly interface and safety features contribute to a seamless operational experience, making them a preferred choice in settings requiring high precision.

Maintenance and Sustainability

Maintenance of a precision boring machine is straightforward, with accessible components and clear maintenance protocols. Sustainability is also a consideration, with many machines designed to operate with minimal waste and energy consumption, reflecting the industry's move towards greener manufacturing practices.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4