Popular in your industry

Related Searches:

Top categories

About bending machine nargesa

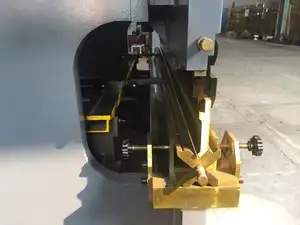

Introduction to Bending Machine Nargesa

The bending machine Nargesa is a cornerstone in the metal fabrication industry, known for its efficiency and precision. This equipment is designed to manipulate metal sheets and bars into various angles and shapes, catering to a wide array of industrial applications. Its rapid operation not only accelerates production rates but also enables manufacturers to bring metal bending processes in-house, optimizing costs and enhancing quality control.

Operational Efficiency and Waste Reduction

One of the primary attributes of the bending machine Nargesa is its operational efficiency. The swift processing of materials ensures that production timelines are met without compromising on the quality of the output. Additionally, the advanced design of these machines minimizes metal wastage, ensuring that every inch of material is utilized effectively, which is crucial in today's resource-conscious environment.

Versatility and Applications

Versatility is another significant advantage of the metal bending machine. Capable of handling a diverse range of materials and thicknesses, these machines are indispensable for creating components across various sectors such as automotive, construction, and aerospace. The adaptability of the Nargesa range allows for customization in sheet metal work, providing the flexibility needed for specialized projects.

Safety and Precision in Metalworking

Safety is paramount in any industrial setting, and the sheet metal bender addresses this by featuring hemming capabilities. Hemming involves folding the edges of metal sheets to create a safe, rounded finish, thereby reducing the risk of accidents during handling. This process not only ensures the safety of workers but also contributes to the precision and aesthetic quality of the final product.

Considerations for Purchase

When selecting a hydraulic bending machine, several factors must be considered to ensure it meets the specific needs of your operation. The tonnage, or bending force, is critical for determining the machine's capability to shape metal. Additionally, the bending length must be compatible with the size of the materials being worked on. Space is also a consideration; the machine's dimensions should fit within the designated work area without necessitating extensive rearrangements.

Choosing the Right Machine on Alibaba.com

For businesses seeking a steel bending machine, Alibaba.com offers a comprehensive selection to suit various preferences. The platform's extensive catalog ensures that you can find a machine that aligns with your operational requirements and production goals. With a user-friendly interface, Alibaba.com facilitates an efficient procurement process, allowing buyers to connect with suppliers and secure the equipment they need to advance their manufacturing capabilities.