Popular in your industry

Top categories

About ball screws

What are Ball Screws

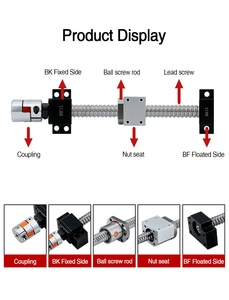

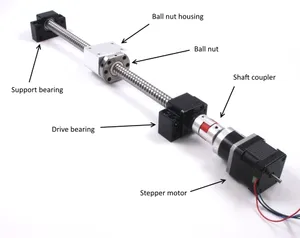

Ball screws are precision mechanical devices used to convert rotational motion into linear motion with minimal friction. They are composed of a screw with a helical groove and a ball nut with matching grooves, where a series of bearing balls circulate. These components work together to provide a highly efficient and accurate means of achieving linear motion, making ball screws an essential part of many types of machinery.

The principle behind the ball screw's functioning is quite simple yet ingenious. As the screw rotates, the balls roll along the helical tracks on the screw and nut, transferring the rotary motion into precise linear movement. This rolling action reduces friction significantly when compared to traditional lead screws, where sliding friction is involved. The reduced friction not only enhances performance but also prolongs the lifespan of the device.

Ball screws are utilized across various industries, including aerospace, automotive, and manufacturing, due to their ability to deliver precise and controlled movement. They are especially prevalent in machine tools like CNC machines, where they drive the movement of cutting tools and workpieces with high accuracy and repeatability. Similarly, in robotics and precision assembly equipment, ball screws are favored for their reliability and precision.

Types of Ball Screws

Ball screws can be categorized based on their design and manufacturing process, which directly impact their performance characteristics and suitability for different applications.

Precision Ground Ball Screws: These ball screws are manufactured by grinding, ensuring high accuracy and smooth motion. They are ideal for applications requiring precise control and high load capacity, such as in aerospace and high-end CNC machines.

Rolled Ball Screws: Rolled ball screws are produced by cold rolling and are generally more cost-effective than ground screws. While they offer slightly lower precision levels, they are still suitable for a wide variety of applications including industrial automation and machinery.

Miniature Ball Screws: Designed for small-scale applications, miniature ball screws provide high precision in compact spaces. They are commonly found in medical devices, small robotics, and semiconductor manufacturing equipment.

High Lead Ball Screws: These ball screws have an increased lead (the distance the nut moves with one screw revolution), which allows for faster movement. They're suitable for applications needing rapid motion over shorter distances.

Each type serves specific use cases, balancing factors like precision, load capacity, speed, and cost-effectiveness.

How to Choose Ball Screws

Selecting the right ball screw for your business involves considering several factors that align with your application's demands. Since Alibaba.com caters to B2B sales with a focus on businesses using components commercially or reselling them in bulk, it is vital to understand these considerations thoroughly.

Precision Requirements: Evaluate the level of precision needed for your application. For instance, ground ball screws offer higher precision than rolled ones and might be necessary for advanced CNC machining or aerospace applications.

Load Capacity: Determine the load the ball screw must support. Heavier loads may require robust ball screws made from stronger materials or designed with specific load capabilities in mind.

Desired Speed: Consider the speed at which the ball screw will operate. High lead screws can move quickly but may not be as precise as other types with smaller leads.

Manufacturing Process: The choice between rolled or ground ball screws will affect both cost and performance. Ground screws are more precise but also more expensive than their rolled counterparts.

Application Environment: The environment in which the ball screw will operate can dictate material choice (such as corrosion-resistant stainless steel) and sealing options to protect against contaminants.

By assessing these parameters alongside Alibaba.com’s extensive selection of ball screws from various suppliers worldwide, businesses can make well-informed decisions tailored to their unique needs.

Best Ball Screws on Alibaba.com

Alibaba.com stands out as a global marketplace connecting buyers with suppliers of high-quality industrial components like ball screws. With an extensive network encompassing over 190 countries and areas, businesses can find a comprehensive range of ball screw options suitable for any application—from manufacturing plants to CNC setups or even home use projects.

The platform values ease of use and efficiency; therefore, it offers features such as mobile-friendly buying processes and multilingual communication capabilities. This user-centric approach ensures that regardless of your business size or industry need, you can source the right products seamlessly. Moreover, Alibaba.com's Trade Assurance service adds an extra layer of security by safeguarding payments until delivery is confirmed, demonstrating a commitment to transaction reliability.

Choosing Alibaba.com as your go-to source for wholesale ball screws ensures that your business benefits from a vast selection of products verified for quality. Whether you're seeking customization options or standard off-the-shelf components, Alibaba.com is designed to meet diverse commercial needs while upholding trustworthiness in global trade partnerships.

Common FAQs for Ball Screws

What is a ball screw?

A ball screw is a mechanical device that converts rotational motion into linear motion. It consists of a screw shaft with a helical groove and a ball nut with matching grooves, where bearing balls circulate to reduce friction.

How do ball screws differ from lead screws?

Ball screws use rolling elements (balls) to reduce friction and increase efficiency, while lead screws typically have direct contact between the threading of the screw and the nut, resulting in higher friction and less efficiency.

What are the advantages of using ball screws in machinery?

Ball screws offer high precision, efficiency, and load-carrying capacity with reduced friction, making them ideal for applications requiring accurate and repeatable linear motion.

How do I determine the right ball screw for my application?

Consider factors such as the required precision, load capacity, speed, manufacturing process, and application environment to select a ball screw that meets your specific needs.

Can ball screws be used in vertical applications?

Yes, ball screws are suitable for vertical applications as they can efficiently convert rotational motion into precise vertical linear movement.

Are there different grades of precision for ball screws?

Yes, ball screws are available in various precision grades, such as P0 to P5, with P0 being the least precise and P5 being the most precise.

What materials are commonly used for manufacturing ball screws?

Ball screws are typically made from materials like steel, stainless steel, or bearing steel to ensure durability and strength.

What is the difference between rolled and ground ball screws?

Rolled ball screws are produced by cold rolling and are more cost-effective with slightly lower precision. Ground ball screws are made by grinding for higher accuracy and smoothness.

How do I maintain a ball screw system?

Regular maintenance includes lubrication to reduce wear and tear, cleaning to remove debris or contaminants, and inspection for signs of wear or damage.

Can I customize a ball screw for my specific needs?

Many suppliers offer customization options for ball screws to meet unique application requirements such as specific lengths, diameters, leads, or end machining.

What is backlash in a ball screw assembly?

Backlash refers to the axial play between the screw and nut in a ball screw assembly. It's the amount of lost motion due to clearances within the system when changing directions.

How does temperature affect the performance of a ball screw?

Temperature changes can cause thermal expansion or contraction of the ball screw material, potentially affecting its precision and alignment. Proper design considerations must be made for applications with significant temperature variations.

What lubrication options are available for ball screws?

Ball screws can be lubricated with grease or oil. The choice depends on the application's requirements regarding speed, temperature, and maintenance intervals.

Can I use a single ball screw for heavy loads?

It's important to assess the load rating of a ball screw. For very heavy loads, multiple ball screws might be required or one with a specific design capable of handling such loads.

What after-sales services are typically provided with ball screws?

After-sales services can include online support, video technical support, or field maintenance and repair services offered by suppliers.

Are there any sealing options for ball screws used in harsh environments?

Yes, there are sealing options like caps or seals that protect the internal components from dust, chips, and other contaminants common in harsh environments.