Popular in your industry

Related Searches:

Top categories

About aluminum rail bending machine

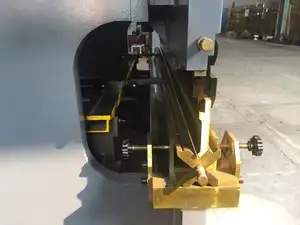

Introduction to Aluminum Rail Bending Machines

Aluminum rail bending machines are essential tools in the fabrication industry, designed to manipulate aluminum rails into various curves and angles with precision. These machines streamline the production process, ensuring that project timelines are met efficiently, which in turn can enhance the reputation of a business. The automation of these machines minimizes the need for manual labor, reducing operational costs and the necessity for extensive operator training.

Types and Applications

The versatility of aluminum rail bending machines is evident in their ability to perform multiple bending techniques such as V-bending, wipe bending, rotary bending, and step bending. This flexibility makes them suitable for a wide range of applications in industries like construction, automotive, and aerospace where the shaping of aluminum profiles is required.

Features and Precision

One of the standout features of an aluminum profile bending machine is its precision. The automated control ensures that each bend is consistent, reducing material waste and ensuring that the end products are of uniform quality. This level of accuracy is crucial for maintaining standards in production and avoiding costly errors.

Material Considerations

When selecting an aluminum bending machine, it is important to consider the type of aluminum material to be bent. Machines are calibrated to handle specific material thicknesses and compositions to produce the desired shapes without compromising the metal's integrity. Ensuring that the machine is compatible with the material is key to achieving optimal bending results.

Machine Durability and Maintenance

Durability is a significant factor when investing in an aluminum rail bender. A robust machine can withstand the demands of continuous operation. Maintenance is also a consideration; over time, certain parts may need replacement due to wear and tear. Therefore, the availability of spare parts is crucial to minimize downtime and maintain productivity.

Choosing the Right Machine

In the procurement of an aluminum rail bending machine, factors such as the bending radius capabilities and warranty should be evaluated. A warranty provides a form of assurance regarding the machine's reliability within a certain timeframe. For a comprehensive selection of profile bending machines, Alibaba.com offers a platform where various suppliers showcase their machinery, allowing buyers to compare and make informed decisions without the pressure of brand influence.