Popular in your industry

Related Searches:

Top categories

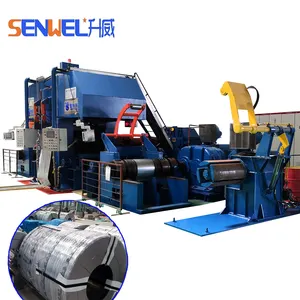

About aluminum cold rolling mill

Introduction to Aluminum Cold Rolling Mills

Aluminum cold rolling mills are specialized industrial setups designed to process aluminum into various thicknesses and grades. These mills employ the cold rolling process, which involves rolling aluminum at room temperature to achieve a more uniform and precise thickness. The aluminum cold rolling mill is a critical component in the production of aluminum sheets, coils, and strips, serving a multitude of industries from automotive to construction.

Types and Applications

The versatility of cold rolling aluminium mills is evident in the variety of types available, each suited to specific needs and applications. From single-stand mills for small-scale production to multi-stand tandem mills for high-volume output, the range is extensive. These mills are pivotal in producing flat-rolled aluminum products used in lightweight, high-strength applications, including aerospace components, automotive bodies, and consumer electronics.

Features and Materials

An aluminium cold rolling mill stands out for its features designed to enhance precision, control, and efficiency. The mills are constructed from robust materials capable of withstanding the immense forces of the rolling process. Advanced features may include automated gauge control systems and state-of-the-art drives that ensure consistent thickness and surface quality of the rolled aluminum.

Advantages of Cold Rolling Aluminum

The process of cold rolling aluminum offers several advantages. It improves the mechanical properties of aluminum, enhancing its strength and hardness. The cold rolling process also allows for tighter tolerances and better surface finishes, making it a preferred method for producing high-quality aluminum products that require precise dimensions and aesthetic appeal.

Selection Considerations

When exploring options for an aluminum cold rolling mill, factors such as mill type, capacity, and technological features should be considered. It is important to select a mill that aligns with the specific production requirements and can handle the desired aluminum alloys and thicknesses. Additionally, the choice of control systems can significantly impact the efficiency and quality of the output.

Environmental and Efficiency Aspects

Modern aluminum cold rolling mills are increasingly designed with environmental and efficiency considerations in mind. These mills aim to reduce energy consumption and increase recycling capabilities, ensuring a more sustainable production process. By incorporating advanced technologies, mills are able to achieve higher productivity while minimizing their environmental footprint.