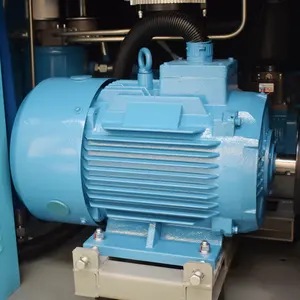

Cải tạo ngôi nhà hoặc cơ sở kinh doanh của bạn với những điều kỳ diệu và cao cấp. máy nén khí ở ấn độ có sẵn tại Alibaba.com với mức chiết khấu vô song. Các. máy nén khí ở ấn độ chứa đầy những đặc điểm nổi bật có được từ các công nghệ và cải tiến tiên tiến tạo ra những thiết kế tuyệt đẹp để mang lại kết quả đầu ra tối ưu. Các. máy nén khí ở ấn độ được sản xuất từ các vật liệu chắc chắn và bền, mang lại tuổi thọ cao đồng thời hiệu quả nhất quán. Chúng nâng cao hiệu quả, năng suất và lợi nhuận của người dùng.

Với nhiều lựa chọn. máy nén khí ở ấn độ chứa các tính năng và đặc điểm khác nhau, tất cả các loại người mua sắm đều được đảm bảo tìm thấy các đối tượng phù hợp hoàn hảo với yêu cầu của họ. Các. máy nén khí ở ấn độ có sẵn ở các kích thước và khả năng xử lý khác nhau để phù hợp với các nhu cầu sản xuất khác nhau cho các doanh nghiệp và cá nhân .. Người bán máy nén khí ở ấn độ trên Alibaba.com được xem xét kỹ lưỡng để đảm bảo rằng họ tuân thủ tất cả các tiêu chuẩn chất lượng.

Các nhà sản xuất chúng. máy nén khí ở ấn độ được xác định để thúc đẩy tính bền vững. Họ sử dụng các phong cách và kỹ thuật sắc sảo để giảm thiểu tiêu thụ điện trong khi vẫn giữ được hiệu suất cao nhất. Hãy tận dụng thuộc tính tuyệt vời này của. máy nén khí ở ấn độ và giảm hóa đơn tiền điện của bạn. Các. máy nén khí ở ấn độ kết hợp các nguyên tắc cài đặt của họ cũng như các quy tắc an toàn để trao quyền cho người dùng gặt hái lợi ích của họ ngay sau khi mua. Bất chấp những nguyên tắc này, bạn có thể liên hệ với người bán bất cứ lúc nào để được hỗ trợ thêm.

Bạn có thể nghĩ rằng nhiều tính năng mong muốn sẽ khiến bạn phải trả giá đắt. Ngược lại, chúng có giá cả phải chăng hơn bạn nghĩ rất nhiều. Khám phá nhiều loại. máy nén khí ở ấn độ trên Alibaba.com và tận hưởng những ưu đãi hấp dẫn. Có được đáng tin cậy. máy nén khí ở ấn độ ngay hôm nay và nâng cao năng suất trong gia đình hoặc doanh nghiệp của bạn.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4