Độ chính xác cao 1500W 2000W 3000W sợi kim loại máy cắt laser

Máy Cắt Laser Sợi Nóng Bán Chạy Với Giảm Giá Cao Cho Thép Không Gỉ Carbon 1500W

Nhà Máy Giá Rẻ Giá Thân Thiện Với Môi 7000W 8000W 9000W Nặng Nhiệm Vụ Máy Cắt Laser Xuất hiện Có Thể Được Tùy Chỉnh

6KW CNC sợi Máy cắt laser CNC máy cắt laser tấm kim loại ống Laser máy cắt

Máy Cắt Laser Bằng Thép Không Gỉ CNC Tấm Kim Loại 1530 Máy Cắt Laser

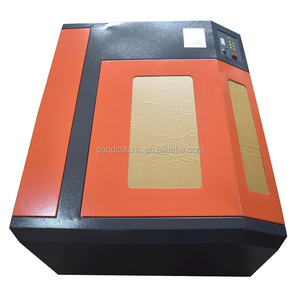

Mô Hình Kiến Trúc Làm Cho Mdf Acrylic Ván Ép Laser Máy Cắt Với 600X400Mm LM-6040

Máy Cắt Laser Mini JULONG 4040 Máy Khắc Laser Co2 4040 40W Khu Vực Làm Việc 400X400 Mm

Máy Cắt Laser Co2 40W 50W/Máy Cắt Laser Và Máy Khắc Ống Laser Reci 4040 400*400Mm

Bán buôn có thể điều khiển CO2 máy cắt laser 1325 400 Watt CO2 Máy cắt laser laser cắt CO2 máy

400*600 6090 80 Wát 100 wát CO2 máy cắt laser với máy làm lạnh nước cw3000 công cụ khắc laser

Laser Khắc Và Cắt Máy Co2 Cnc Laser Lazer Cutter Laser Engraver Da Gỗ Máy Khắc

Máy Khắc Laser 6040 50W 60W 100W 4060, Máy Khắc Laser CO2 Acrylic

Máy Cắt Laser 4040 Máy Khắc 40W/50W/60W CO2 Laser Cho Ván Ép Gỗ Acrylic

Máy Cắt Laser Acrylic Gỗ Co2 Mức Độ An Toàn Cao 400*600 Máy Khắc Laser Máy Khắc Phi Kim Loại

Máy Khắc Laser Cnc Co2 Để Bàn Máy Cắt Laser Co2 Máy Khắc Laser Co2

Atomstack S10 X7 A10 Pro Laser Engraver 10 Wát đầu ra Diode 50 Wát DIY Cutter cho 20 mét gỗ 15 mét Acrylic máy khắc laser

Bán Hot 60 Wát 80 Wát 100 Wát Máy Khắc Laser 4060 6090 CCD Camera Co2 Máy Cắt Laser

600*400Mm 6040 Khắc Cutter Thống 40W 50W 60W 80W 100W Co2 Laser Máy Khắc Laser Máy Cắt Cho Phi Kim Loại

Máy Cắt Khắc Laser 4060 Đa Chức Năng/Máy Cắt Laser CNC Co2 Máy Khắc Xoay Tiêu Chuẩn/Đơn Giản CW5000/3000 Để Lựa Chọn

50W 60W 80W 100W 130W 4060 6090 1390 Gỗ Nhựa Da Acrylic Cao Su Khắc Laser Thủy Tinh Máy Cắt

Máy Khắc Laser CNC 4040 15W Tự Làm Máy Khắc Gỗ Để Bàn Máy Khắc Laser

Máy Khắc Laser Mini K40 60W 80W Ruida Square Guide Rail

HT-460 Laser Haotian 400*600Mm 4060 Máy Khắc Và Cắt Laser CO2

Chất lượng cao 3 trục CNC dọc thủy tinh Laser khoan và máy phay với 3D năng động tập trung Máy quét đấm thủy tinh chế biến

Kính chính xác cắt chip điện tử mỏng tấm kim loại kính thủy tinh picosecond máy cắt laser

Chất lượng cao 4040 400*400 mét CO2 máy khắc laser 50 Wát 60 Wát gỗ Acrylic vải da Máy cắt laser

Máy Cắt Laser Đầu Đôi Tốc Độ Cao Cho Quần Áo Dệt May Gia Đình Và Các Ngành Công Nghiệp Khác

60W Co2 3D Laser Crystal Glass Engraver Máy Khắc Để Bán UK Với Máy Ảnh

400*400 Mm Picoway Máy Laser Cho Cắt Khắc Thủy Tinh Và Nhôm

Máy Cắt Laser Giấy Acrylic Gỗ MDF Máy Khắc Laser 4060 60W 80W 100W CO2 Cnc 4060 Máy Cắt Laser

Giá Máy Cắt Laser Phi Kim Loại Với Ống Laser CO2 60W 80W 100W 130W 150W 200W

Atomstack S20 Pro 130W 410*400mm khắc laser đá da ván ép tấm kim loại mini xách tay CNC cắt Khắc Máy

300*400 Mm Xách Tay Mini Co2 Máy Khắc Laser 40 W 50 W 60 W

Nhỏ A3 A4 Kích Thước Giấy Cao Su Máy Cắt Laser

Máy Khắc Laser Bán Chạy Máy Khắc Laser Co2 4060 Máy Cnc 4060 50W 60W

ATOMSTACK S20 X20 A20 PRO 130W 400*850Mm Ván Ép MDF Di Động Máy Cắt Khắc Laser Diode Nhỏ Bằng Kim Loại Gỗ

Máy Cắt Laser Rộng Rãi Để Bán Máy Cắt Laser Máy Khắc Để Bàn 60W

Bluetimes 410x400 mét khu vực làm việc với không khí hỗ trợ DIY 5 Wát 10 Wát Diode Laser Engraver khắc máy cho gỗ

Máy Khắc Laser Mới SCULPFUN S30 90W Máy Khắc Laser Diện Tích Lớn Bo Mạch Chủ Gỗ Kim Loại Tự Làm 32 Bit

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4