A 4 x 8 melamine sheet is a highly adaptable construction material, extensively employed in various domains ranging from furniture creation to cabinetry. These sheets are esteemed for their robustness, simple upkeep, and the assortment of finishes on offer. The 4x8 melamine panel is particularly favored for crafting contemporary office furnishings, kitchen cabinetry, and assorted storage options, providing both functionality and an attractive finish.

Types and Applications of 4 x 8 Melamine Sheets

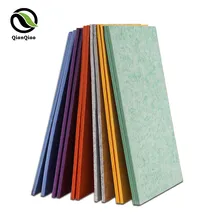

The 4 x 8 melamine board is available in a plethora of types, each distinguished by its own set of attributes. The white melamine board 8x4 is sought after for its ability to create luminous, immaculate environments, while textured variants offer a tactile experience akin to natural wood, infusing spaces with a sense of warmth. High-gloss options cater to those desiring a polished, modern aesthetic, and matte finishes are selected for their subdued, non-reflective qualities. These boards are not confined to indoor use in offices, hotels, and residences; they are equally prevalent in outdoor settings and supermarket installations. The 8x4 melamine sheets are lauded for their adaptability to diverse settings, making them a staple for builders and designers. Their scratch and stain resistance render them perfect for bustling commercial areas, such as retail counters or office worktops. In educational institutions, they withstand the intense usage by students as sturdy workstations and shelving. In the healthcare sector, the non-porous nature of these surfaces is prized for its sanitary benefits, ideal for medical storage and work areas.

Structure and Material Composition

The core of a 4x8 melamine plywood typically consists of wood fiber or poplar, materials chosen for their balance of lightness and strength. A melamine-infused paper, available in wood grain, natural, or brown, is affixed to this core through a process of heat and pressure, resulting in a resilient, even surface. The edges of these panels can be treated with edge banding or similar enhancements to improve their durability and visual appeal. The construction of these sheets is meticulously engineered to maintain stability and resist warping, making them suitable for a broad spectrum of temperature and humidity conditions. Often, the internal structure is bolstered with additional materials to augment strength and prevent bending, ensuring the melamine sheets can bear considerable weight without sustaining damage.

Materials and Their Properties

The constituents of 4x8 melamine panels are selected for their enduring nature and performance. Wood fibers lay the foundation for stability, while the melamine resin bestows the sheets with a hard, impermeable exterior. This fusion renders the sheets resistant to moisture, heat, and chemical agents. The melamine's surface is also non-porous, which inhibits bacterial growth, making it an exemplary choice for settings such as kitchens and healthcare facilities. These materials also facilitate ease of cleaning and maintenance, contributing to the product's longevity. Melamine's inherent qualities include resistance to fading and discoloration, ensuring that the product maintains its appearance even under prolonged exposure to sunlight or cleaning substances.

Business Usages and Applications

In the commercial sphere, 4 x 8 melamine sheets are deployed across a multitude of industries. In retail, they form the backbone of robust and visually appealing shelving and display units. Within the hospitality sector, they are crafted into tabletops and counters that endure constant sanitation and heavy usage. In office environments, they are transformed into desks, cubicles, and other furniture that demand a professional look and resilience. These applications underscore the material's capacity to deliver business value through enduring, low-maintenance solutions that withstand the demands of commercial activity. In manufacturing, melamine sheets serve as a substrate for countertops and other surfaces requiring a durable laminate coating. The construction industry appreciates melamine for its straightforward installation and the efficiency it brings to the building process, reducing labor costs and expediting completion times.

Functions and Tasks

The primary role of a 4 x 8 melamine sheet is to furnish a solid, flat surface that stands up to wear and tear. It is crafted for environments where a robust, easily sanitized surface is essential. These sheets can be tailored through cutting and drilling to a variety of shapes and sizes, rendering them highly versatile for bespoke furniture, cabinetry, and architectural features. The flexibility of melamine sheets enables them to fulfill multiple roles, both structural and decorative. They can function as a writing surface in educational settings, a waterproof barrier in bathrooms, or as an ornamental element in home theaters, showcasing their multifaceted utility.

Distinctive Features and Capabilities

The 4x8 melamine plywood is distinguished by its low-maintenance nature and its resilience to common challenges such as stains and abrasions. The array of finishes available allows for creative design choices, while the product's consistency ensures uniformity across extensive projects. These characteristics, coupled with the material's resistance to environmental factors, position it as a compelling option for businesses in search of reliable and appealing construction materials. The potential for customizing the surface with digital prints or patterns further elevates its desirability, permitting personalized designs that can mirror a corporate identity or individual style preferences.

Benefits and Positive Outcomes

Employing 4 x 8 melamine sheets yields a multitude of advantages, including cost efficiencies owing to their durability and minimal upkeep. They address the need for a resilient surface that endures daily wear without sacrificing aesthetic appeal. For enterprises, this equates to reduced replacement and repair frequency, enhancing profitability. For end-users, it signifies a dependable product that preserves its look over time, fostering a favorable impression of the space. The health advantages are also noteworthy, as the non-porous surface deters the proliferation of mold and bacteria, promoting cleaner, healthier environments.

How does the quality of base material affect the durability of melamine sheets?

The foundational material, often hardwood or poplar, is pivotal to the longevity of 4x8 melamine panel. Hardwood provides a denser, more formidable base, whereas poplar offers a lighter, yet robust alternative. The selection of base material influences the sheet's resistance to warping and its capacity to preserve structural integrity over time. The caliber of the base also impacts the sheet's ability to secure screws and fasteners, a critical aspect for furniture assembly and architectural uses.

What are the considerations when choosing the right melamine sheet for a project?

In choosing a 4 x 8 melamine sheet for a project, one must contemplate the intended use, the environmental conditions of the area, the desired design aesthetic, and compliance with formaldehyde emission standards. It is equally important to evaluate the supplier's after-sale services on Alibaba.com, such as on-site installation or instructional offerings, which may be vital for intricate undertakings. Factors like weight capacity, finish type, and color choices should also be taken into account to ensure the product aligns with the project's specific requirements.

How to maintain and clean melamine sheets to ensure longevity?

To maintain and cleanse 4x8 sheet white melamine, regular dusting with a damp cloth is recommended to address spills and dust accumulation. It is advisable to steer clear of abrasive cleaning agents or pads that could mar the surface. For more stubborn stains, a gentle detergent may be employed. Adhering to proper maintenance protocols will guarantee that the melamine sheets' aesthetic appeal and longevity are preserved. Additionally, it is wise to avoid placing intensely hot items directly on the surface, as extreme temperatures can compromise the melamine coating.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4