Popular in your industry

Related Searches:

Top categories

About 300ton metal bending machine

Introduction to 300ton Metal Bending Machines

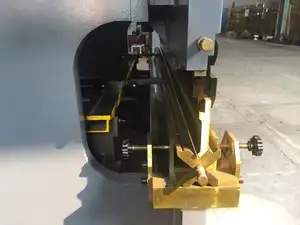

The 300ton metal bending machine stands as a pivotal piece of industrial equipment designed for shaping and manipulating metal sheets with precision and efficiency. This category of machinery is integral to operations in various sectors, including automotive, aerospace, and construction, where metal components with specific bends and folds are requisite.

Technical Specifications and Types

Understanding the technical nuances of a heavy-duty bending machine is crucial for optimal utilization. These machines are characterized by their tonnage, or bending force, which dictates their capability to work with different metal thicknesses and types. The bending length is another critical specification, determining the maximum length of metal sheet that can be processed. Various types of bending machines exist, including hydraulic press brakes, CNC bending machines, and manual benders, each suited to particular applications and workloads.

Applications and Versatility

The application range of a sheet metal bender is extensive, catering to the production of metal structures, frames, and panels. Its versatility is highlighted by its ability to handle various materials such as steel, aluminum, and copper, making it a valuable asset for manufacturers requiring diverse metal components. The adaptability of a 300ton press brake extends to its hemming capabilities, which involve folding the edges of metal sheets to enhance safety and aesthetics.

Features and Advantages

A precision metal bending machine comes with an array of features designed to enhance productivity and reduce waste. Speed is a paramount advantage, directly influencing production rates and project timelines. The in-house operation of a CNC metal bending machine allows for greater control over the manufacturing process, ensuring adherence to specifications and reducing reliance on external services. Additionally, the minimization of metal wastage not only cuts costs but also supports sustainable manufacturing practices.

Considerations for Purchase

Selecting a 300ton metal bending machine requires careful consideration of several factors. The machine's dimensions must be compatible with the available workspace, and the tonnage should align with the intended metalworking tasks. Prospective buyers should evaluate the machine's compatibility with their existing operations, considering factors such as material types and required bending lengths. While exploring options, it is advisable to compare the features of different machines to identify the one that best meets the operational needs without specific endorsements of price or brand.

Conclusion

For businesses seeking to enhance their metalworking capabilities, the 300ton metal bending machine offers a blend of speed, versatility, and precision. As a category, these machines are indispensable for industries requiring high-volume, accurate metal bending operations. Prospective buyers are encouraged to conduct thorough research to select a machine that aligns with their production requirements and workspace constraints.