Popular en tu industria

Categorías principales

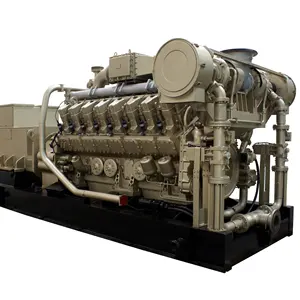

Sobre 1mw central de gas

Parte del combustible de quema más limpia está 1mw central de gas . Y estos están disponibles en Alibaba.com. Ayudando a satisfacer la creciente demanda de mejores fuentes de energía en todo el mundo, estos 1mw central de gas . son fáciles de enviar y proporcionan un combustible de menor emisión que otros productos de gas.

usando 1mw central de gas . significa que el combustible no se agota, ya que no habrá interrupciones para suministrar tormentas u otras razones gracias a los productos en alibaba.com. A diferencia de otras fuentes de combustible que dejan cenizas y olores, estos productos nunca dejarán un desastre. Estos productos son convenientes para proporcionar calor, precisión e incluso agua caliente a una casa completa. A pesar de que estos artículos se usan principalmente para el calor, son increíblemente versátiles y también se pueden usar al aire libre para cocinar y calentar bañeras y piscinas de calefacción de barbacoa.

The 1mw central de gas . Puede ahorrar mucho dinero gracias al bajo precio de los productos y son algunas de las mejores fuentes de energía para comprar. De hecho, son algunas de las fuentes más seguras de energía y son utilizadas por millones de personas en todo el mundo en hogares y negocios. Todos los electrodomésticos se convierten fácilmente en el uso de estos combustibles y hay enormes beneficios ambientales para estos productos, ya que son muy bajos en emisiones. Debido a que los productos se queman, cualquier equipo que use este gas necesitará mucho menos mantenimiento y reparaciones a lo largo de los años.

Encuentre asequible 1mw central de gas . Etiquetas en Alibaba.com para fuentes de energía sostenibles y renovables. Estos productos provienen de varios proveedores y están disponibles en múltiples formas. Disfrute de una fuente limpia de combustible y compre en línea hoy.