Beliebt in Ihrer Branche

Top-Kategorien

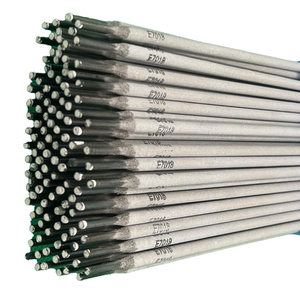

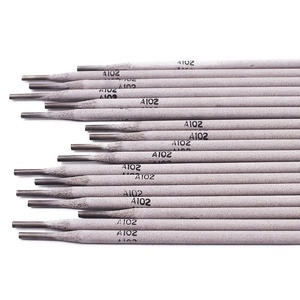

Über 1mm elektrode

Durchsuchen Sie internationale Angebote und finden Sie 1mm elektrode, elektrolumineszierende Nachtlichter, Kabel, Kleidung, Klebstoffe und vieles mehr für Ihr Unternehmen. Elektrolumineszenz oder EL ist das optische und elektrische Phänomen, das auf der Emission von Photonen durch angeregte Atome beruht. Dies kann mit einem Phosphor-Elektrolumineszenzfilm oder LED-Leuchten geschehen. Diese Technologie wird dann verwendet, um einen leuchtenden Elektrolumineszenzdraht, eine Tafel, Farben, Klebebänder, Streifen und andere Arten von Gegenständen herzustellen. Wenn Strom von einer Batterie oder einer Steckdose durch sie fließt, leuchten sie.

Jedes Elektrolumineszenz-Panel oder jedes andere 1mm elektrode dieser Art benötigt Elektrizität zum Leuchten. Für den Phosphor-Elektrolumineszenzdraht wird beispielsweise eine Phosphorröhre mit zwei Drähten in Wechselstrom verbunden. Dieser Strom lässt ihn glühen, wenn er mit dem Phosphor in Kontakt kommt. Diese Komponenten werden dann in eine elektrolumineszierende Folie mit einem Isolatormaterial eingeschlossen. Es ist wichtig, einen Wechselrichter zu verwenden, wenn Gleichstrom zum Beleuchten eines EL-Kabels verwendet wird. Nur Wechselstrom sollte mit dem Elektrolumineszenzstreifen in Kontakt kommen.

Auf Alibaba.com haben Sie Zugang zu internationalen Lieferanten für Großhandel 1mm elektrode, EL-Panel-Leuchten, Elektrolumineszenzleuchten und vieles mehr. Kaufen Sie Elektrolumineszenzband direkt vom Hersteller und decken Sie Ihr Geschäft auf.