Popular in your industry

Related Searches:

Ready to Ship

Ready to Ship

Top categories

About preform pet bottle making machine

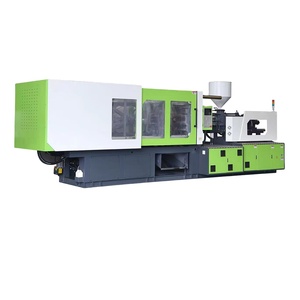

Introduction to Preform PET Bottle Making Machines

The realm of manufacturing is witnessing a revolution with the advent of preform PET bottle making machines. These machines are pivotal in the production of polyethylene terephthalate (PET) bottles, which are ubiquitous in packaging a variety of products. The versatility of these machines allows for the creation of bottles that cater to diverse industry needs, from beverage containers to personal care products.

Types and Applications

There are various types of PET bottle manufacturing machines, each designed to meet specific production requirements. From single-stage to two-stage systems, the machines handle different phases of bottle production, including injection molding of preforms and blow molding to give them the final shape. The applications are extensive, covering areas such as food and beverage, pharmaceuticals, and consumer goods, where the demand for reliable and resilient packaging solutions is constant.

Operational Features

The operational features of PET preform bottle machines are designed for efficiency and ease of use. With options for manual and semi-automatic operations, these machines provide flexibility in production. Advanced models come equipped with automated fuel injection and precision bottle blowing capabilities, ensuring consistent output and minimizing human intervention. The focus on automation within these systems aims to enhance production rates and maintain uniformity in the quality of the bottles produced.

Materials and Sustainability

PET bottle blowing machines are constructed using hardened metals, ensuring longevity and resistance to wear and tear. The choice of materials reflects a commitment to sustainability, as these machines are capable of enduring heavy usage while minimizing waste. Additionally, the use of recyclable PET material in the production of bottles underscores the eco-friendly aspect of this packaging solution.

Advantages of Modern Machines

Modern PET bottle making equipment boasts numerous advantages. They are engineered to be energy-efficient, reducing the overall carbon footprint of the manufacturing process. The precision engineering involved in these machines allows for the production of bottles in various shapes and sizes, tailored to specific market requirements. This flexibility is complemented by the machines' energy-efficient design, which not only conserves energy but also reduces operational costs.

Choosing the Right Machine

Selecting the right PET preform bottle production machine involves considering factors such as capacity, size, and specific feature requirements. Alibaba.com hosts a wide array of these machines, allowing buyers to find the perfect match for their production needs. While exploring the options, it is essential to consider the technical specifications and operational efficiencies to ensure that the chosen machine aligns with the intended production goals.