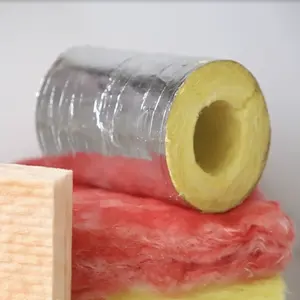

Fiberglass is an insulator for hot and cold service pipes with temperatures from -20 degrees Fahrenheit and up to 1000 degrees Fahrenheit. Fiberglass pipe insulationmaterials are long strands of fiberglass arranged into a roll. These rolls (also called batts) may contain a paper vapor barrier. They are available in many widths, lengths, and thicknesses. In the past, fiberglass pipe covering installation was a risky procedure. Before October 2015, many fiberglass insulations contained formaldehyde, a harmful chemical. Today, the insulation is relatively free of high concentrations of dangerous chemicals. Anyone can install them, provided they have detailed instructions and protective clothing.

Best fiberglass for pipe insulation

All fiberglass materials will do a decent job of insulating your pipes. That said, there are pros and cons to choosing a particular fiberglass. For instance, loose fiberglass is the most difficult option to work with. You must wound the material around the pipe and secure it with tape. During the installation, the fiberglass stands may come loose and become airborne. So you must also protect yourself with gloves, eye protection, and a respirator. Despite their disadvantages, people prefer loose fiberglass because they are cheap.

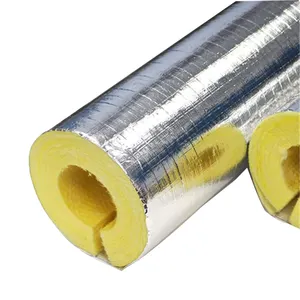

A fiberglass pipe wrap does not have any of these disadvantages. It is easier to install, and it fits the pipe better. Also known as a fiberglass sleeve, fiberglass pipe wrap is more reliable than others. Even better, the wraps are pre-shaped to fit the pips, so you don't need any effort to install them. You slip them on, then seal the seam with tape. The downside is that fiberglass wraps are expensive. If you are on a budget, you may have to choose loose fiberglass insulation materials.

How to install fiberglass pipe insulation

Installing afiberglass steam pipe insulation is simple. In most cases, the manufacturer has provided a set of easy-to-follow instructions. Follow those instructions.

The guideline in this post is for insulating water supply pipes. You can also use it for insulating gas pipes as well. A fiberglass insulation tube aims to trap as much air as possible within the fiberglass. As a result, you want to cover the pipe with as little insulation as possible. The first step is to determine how much insulation is required. Most fiberglass pipe wraps come in increments of 36" to 48". Loose fiberglass insulation comes in R-values, with R-6 batting as the common option.

If you use fiberglass pipe wrap, attach the insulation to the pipe and tape it. For loose fiberglass, you can wound the batting around the pipe, pre-cut it, and install it parallel to it. The second approach prevents overlapping. It is time to tape after you have slipped (or wound) thefiberglass tube insulation. Use the tape to cover the pipe completely. This ensures that no section of the pipe is exposed. Use approved insulation tape to ensure the insulation lasts longer and complies with building codes. Avoid using masking tape, strapping tape, or duct tape.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4