Introduction to Cotton Waste Carding Machines

Cotton waste carding machines are specialized pieces of equipment designed for processing and recycling cotton waste in the textile industry. These machines are essential for converting cotton waste into usable fibers that can be reintegrated into the production cycle, thus contributing to sustainable manufacturing practices.

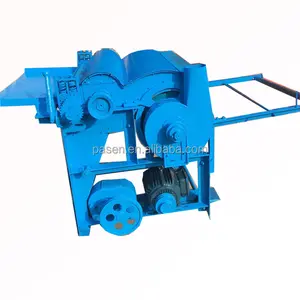

Types and Applications

There are various types of cotton waste carding machines tailored to different processing needs. Some are suited for small-scale operations, while others serve large manufacturing plants. Their applications range from preparing fibers for yarn production to creating nonwoven materials, showcasing their versatility in both home use and commercial garment production.

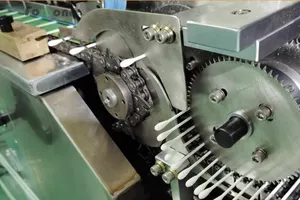

Features and Functionality

A cotton waste carding machine typically features components such as feeders, cylinders, doffers, and condensers. These components work in unison to efficiently open, clean, and align cotton fibers. The machines are designed to handle various grades of cotton waste, ensuring that the output is consistent and suitable for further textile processing.

Materials and Construction

The construction of a cotton waste carding machine involves durable materials capable of withstanding the rigors of textile processing. The choice of materials ensures the longevity of the machine and the quality of the fiber output. The robust design also minimizes maintenance needs, making these machines a reliable component in textile recycling operations.

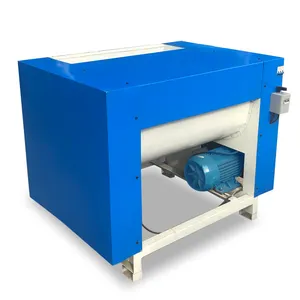

Advantages of Modern Carding Technology

Modern cotton waste carding machines come with advanced features such as automated control systems, which enhance the efficiency and precision of the carding process. These advancements allow for better handling of cotton waste, resulting in higher quality recycled fibers and reduced labor costs.

Support and Services

While Alibaba.com does not directly offer services, the platform lists a variety of suppliers providing cotton waste carding machines with different support options. These may include video technical support and online assistance, ensuring that users can access guidance on machine operation and maintenance as needed.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4