What are Boring Machines

Boring machines are specialized industrial equipment used for enlarging a hole that has already been drilled or cast. The process of boring refers to the precise removal of material from the interior of a workpiece, which allows for the achievement of a particular diameter, concentricity, and surface finish. These machines are essential in various industries such as machinery repair shops, manufacturing plants, and construction where precision holes are required for mechanical components, structures, or assembly processes.

The operation of a boring machine is based on a single-point cutting tool or a boring head containing several cutting tools that rotate while the workpiece remains stationary. The boring process can be performed on various materials, including metals and plastics, and it is fundamental when high precision in terms of alignment and dimension is needed. The desired outcome is achieved by adjusting the tool's position and controlling the cutting speed and feed rate.

Boring machines come in different configurations including horizontal and vertical orientations to accommodate the nature of the workpiece and the specific operation required. They are designed for different scales of work from small, intricate components to large industrial parts. The sophistication of these machines ranges from simple manual operation to highly advanced CNC (Computer Numerical Control) systems which allow for automation and repeatability in mass production environments.

Types of Boring Machines

In the realm of industrial machinery, boring machines come in several variations to suit diverse operational needs. Each type offers distinct features that make it suitable for particular applications:

Horizontal Boring Machine: A common type used for creating precision bores in large workpieces. The horizontal setup provides stability and support for heavy items. It is often utilized in manufacturing plants for complex machinery components.

Vertical Boring Machine: Also known as a vertical turret lathe, this machine operates with a vertical orientation that is well-suited for machining large, heavy workpieces that are relatively short in length. It finds application in industries requiring large part turning like aerospace or shipbuilding.

Jig Borer: Designed for high precision boring operations to achieve tight tolerances. It's commonly used in die-making processes or for creating fixtures that require pinpoint accuracy.

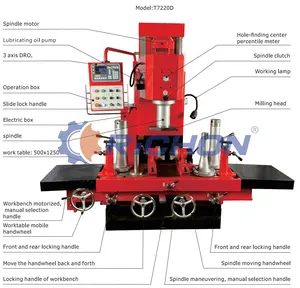

CNC Boring Machine: Equipped with computer controls to ensure high accuracy, repeatability, and efficiency. CNC boring machines are versatile and capable of performing multiple drilling operations with precision. They are used extensively in modern manufacturing environments where complex, repeatable machining is required.

Portable Boring Machine: A compact solution for on-site repair or machining where traditional stationary equipment cannot be used. This type is essential in construction sites, machinery repair shops, or any location where mobility is a key factor.

How to choose Boring Machines

Selecting the right boring machine for your business involves careful consideration of several factors that align with your operational needs. Since Alibaba.com focuses on B2B sales, businesses looking to purchase boring machines should evaluate:

Machine Type and Orientation: Consider whether your applications require a horizontal or vertical setup based on the size and nature of the workpieces you intend to bore. For intricate and very precise operations, a jig borer could be suitable.

Precision Requirements: Assess the level of accuracy needed for your projects. CNC boring machines provide high precision and consistency which may be vital for your production requirements.

Portability: If you need to perform boring operations at various locations or on-site, portable boring machines offer flexibility without compromising performance.

Industry Application: Match the machine capabilities with your specific industry needs—whether it's heavy-duty construction work or delicate manufacturing processes.

Volume and Automation: Consider the volume of work you have. If you need to produce large quantities quickly and consistently, an automated CNC machine would be more beneficial than a manual one.

Best Boring Machines on Alibaba.com

Alibaba.com stands out as a global marketplace connecting buyers with suppliers offering an extensive array of boring machines suitable for any business requirement. With an inventory sourced from over 200,000 suppliers worldwide, companies can find machinery that meets their specific industry needs – from single-spindle units ideal for intricate tasks to multi-axis CNC systems designed for complex production runs.

The platform's user-friendly interface allows businesses to filter through options based on key selling points such as automation level, productivity features, operating convenience, and more – ensuring they find equipment that aligns with their operational goals. Furthermore, Alibaba.com's Trade Assurance service gives added confidence by safeguarding payments until delivery is completed.

For businesses looking to expand their reach or streamline their manufacturing processes, Alibaba.com provides not just a broad selection but also the convenience of mobile buying and multilingual communication support – making it easy to do business anywhere. With its commitment to helping small and medium-sized enterprises grow through effective online trade solutions, Alibaba.com remains an indispensable tool for sourcing commercial-grade boring machines that cater to diverse industrial applications.

Common FAQs for Boring Machines

What is a boring machine used for?

A boring machine is primarily used to enlarge and finish a hole that has already been drilled or cored to a precise size and surface finish. It's an essential tool in industries where accurate holes are needed, such as machinery manufacturing, construction, and repair services.

What are the main types of boring machines available?

The main types of boring machines include horizontal boring machines, vertical boring machines, jig borers, CNC boring machines, and portable boring machines. Each serves different industrial applications and workpiece requirements.

How do I select the right boring machine for my business?

Selecting the right boring machine involves considering factors such as the machine type and orientation, precision requirements, portability needs, specific industry applications, and the volume of work you aim to produce.

Can a boring machine handle different materials?

Yes, boring machines can handle a variety of materials including different metals and plastics. However, the choice of machine and cutting tools should correspond to the material's properties to ensure efficient and precise machining.

What is the difference between a horizontal and a vertical boring machine?

The primary difference lies in their orientation. Horizontal boring machines are suitable for large workpieces that have considerable length, while vertical boring machines (or vertical turret lathes) are better suited for machining large, heavy workpieces with shorter lengths.

Are CNC boring machines more accurate than manual ones?

CNC boring machines offer greater precision and repeatability compared to manual ones. They are equipped with computer controls that automate the machining process and are ideal for complex or high-volume production runs.

What should I consider when looking for high precision in a boring machine?

For high precision, consider features like the machine's spindle accuracy, control system (preferably CNC for consistency), and overall rigidity. Jig borers are also known for their precision in drilling holes with tight tolerances.

How important is portability in a boring machine?

Portability is crucial if you need to perform machining operations at various locations or on-site where stationary equipment is impractical. Portable boring machines provide the flexibility to do so without major sacrifices in performance.

What after-sales services are typically provided with boring machines?

After-sales services for boring machines can include online support, video technical support, field maintenance, repair services, and access to engineers available to service machinery overseas. The specifics may vary by supplier.

Can I customize a boring machine based on my requirements?

Many suppliers offer customization options for boring machines. Custom features can include varying spindle numbers, axes configuration, table sizes, voltage requirements, colors, and more to meet specific operational needs.

How does Alibaba.com ensure the quality of boring machines listed on its platform?

Alibaba.com provides tools for buyers to filter through supplier offerings based on key selling points. Additionally, Trade Assurance helps protect payments until delivery is completed, ensuring suppliers meet the agreed-upon standards.

What industries commonly use boring machines?

Industries that commonly use boring machines include machinery repair shops, manufacturing plants, construction sectors, building material shops, farms, furniture factories, and various others where precise hole-making is required.

What core components should I check when purchasing a boring machine?

When purchasing a boring machine, inspect core components such as the motor, gearbox, bearings, PLC systems (if applicable), gears, pressure vessels (for hydraulic models), pumps, and engines for quality assurance.

Is it possible to get a machinery test report when buying a boring machine?

Yes, some suppliers provide machinery test reports with their equipment. It's essential to confirm whether such documentation is available or not before finalizing your purchase decision.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4