Introduction to Bag in Box Filler Technology

The bag in box filler is a cornerstone in modern packaging solutions, offering a versatile method for dispensing a variety of products. This technology caters to a range of industries, from food and beverage to industrial liquids, ensuring that products are packed efficiently and preserved effectively. The bag in box filling machine operates by inserting and filling bags with liquid or semi-liquid products, then sealing them within a corrugated box for distribution and sale.

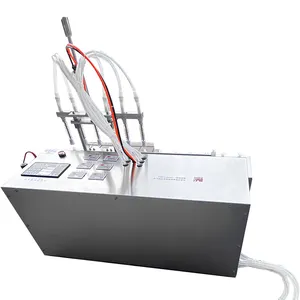

Types and Applications of Bag in Box Fillers

There are several types of bag in box filling equipment available, each designed to meet different industry needs. Manual manual bag in box filler systems are suitable for small-scale operations, while automated solutions cater to high-volume production lines. The applications are extensive, ranging from wine and juice to industrial fluids and chemicals. The adaptability of bag in a box filler systems allows for their use in various settings, emphasizing their importance in today's packaging industry.

Features and Materials

The construction of bag in box filling machines involves materials that ensure durability and compliance with food safety standards. Stainless steel is commonly used for its resistance to corrosion and ease of cleaning. Advanced models may include features like vacuum sealing and nitrogen flushing to extend product shelf life. The aseptic bag in box filling machines take this a step further, offering sterile packaging solutions that are crucial for sensitive products.

Advantages of Bag in Box Filling Systems

Utilizing a bag in box filler presents numerous advantages. These systems are known for their efficiency, capable of packaging products with minimal waste and maximum productivity. The flexibility of bag sizes and box dimensions allows for customization to specific needs. Moreover, the environmental aspect is significant, as the bag in box aseptic filling machine often uses recyclable materials, reducing the carbon footprint associated with packaging.

Complementary Packaging Options

Beyond the primary function of filling, additional packaging materials like shredded gift bag filler and crinkle cut basket filler enhance the presentation and protection of products. For gift baskets, shredded filler for gift baskets adds a decorative touch while also securing items during transport. These complementary options showcase the versatility and comprehensive nature of bag in box packaging solutions.

Choosing the Right Bag in Box Filling Equipment

Selecting the appropriate bag in box filling equipment is crucial for operational success. Factors to consider include production capacity, the viscosity of the product to be filled, and the level of automation required. Whether it's a scholle bag in box filler for high-speed operations or a simpler manual system, the right equipment can significantly impact the efficiency and reliability of the packaging process.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4