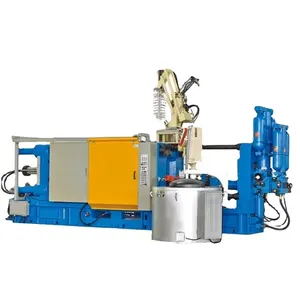

Introduction to Aluminum Casting Machinery

Aluminum casting machinery encompasses a broad spectrum of equipment designed to facilitate the process of casting aluminum into various shapes and forms. This machinery plays a pivotal role in numerous industries, enabling the mass production of aluminum components with precision and efficiency. The versatility of these machines allows for their application in automotive, aerospace, and consumer goods manufacturing, among others.

Types and Applications

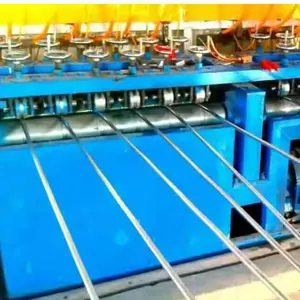

The array of aluminum casting machinery includes several types, each tailored to specific casting methods such as die casting, permanent mold casting, and sand casting. These machines cater to a diverse range of applications, from creating intricate automotive parts to robust construction materials. The adaptability of the machinery to different production scales makes it indispensable for both small-scale operations and industrial giants.

Features and Materials

Modern aluminum casting equipment is engineered with a focus on operational efficiency and durability. The construction of these machines often involves the use of high-grade steel and alloys, ensuring they can withstand the rigors of a demanding production environment. Features may include advanced control systems for precision casting, energy-saving operations, and automation capabilities to reduce manual labor.

Advantages of Utilizing Advanced Machinery

The strategic use of advanced aluminum casting equipment offers numerous advantages. These machines are designed to minimize casting defects, enhance production speed, and improve the overall quality of the final product. Additionally, the robustness of the machinery contributes to a reduction in maintenance needs, ensuring consistent operation and productivity.

Operational Reliability and Safety

Reliability is a cornerstone of aluminum die casting machinery, with many models boasting low failure rates and longevity in operation. Safety is also paramount, with manufacturers incorporating features to safeguard operators against work-related injuries. The availability of spare parts and support for these machines aids in maintaining continuous production, even in the event of component wear or unexpected malfunctions.

Choosing the Right Aluminum Casting Machinery

Selecting the appropriate aluminum casting machine is crucial for meeting specific production requirements. Factors such as the intended application, production volume, and available space will influence the choice of machinery. Prospective buyers are encouraged to consider the technical specifications and performance features of each model to find a machine that aligns with their operational goals.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4